Thanks to everyone for your support and I look forward to what 2019 has in store for us.

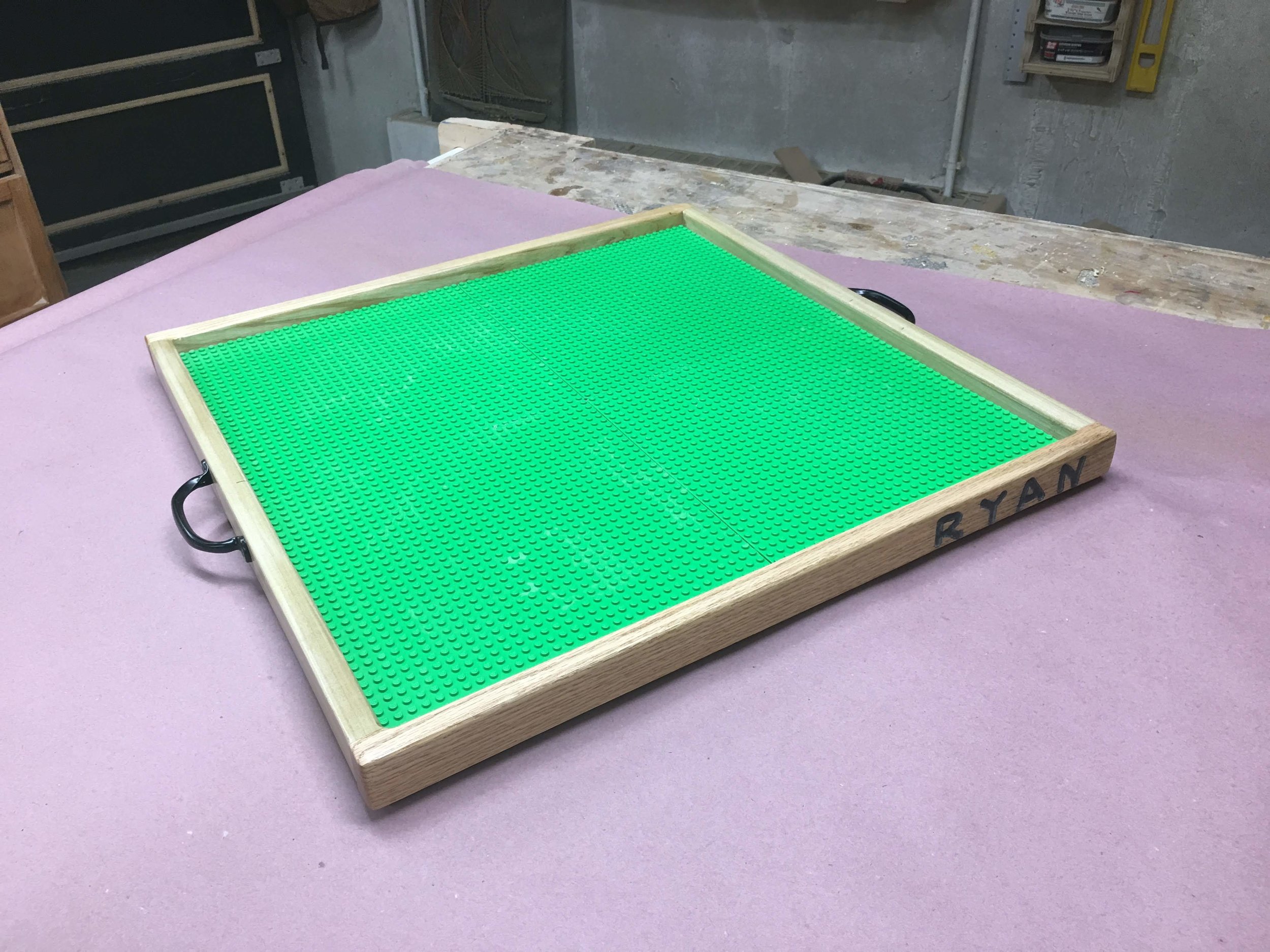

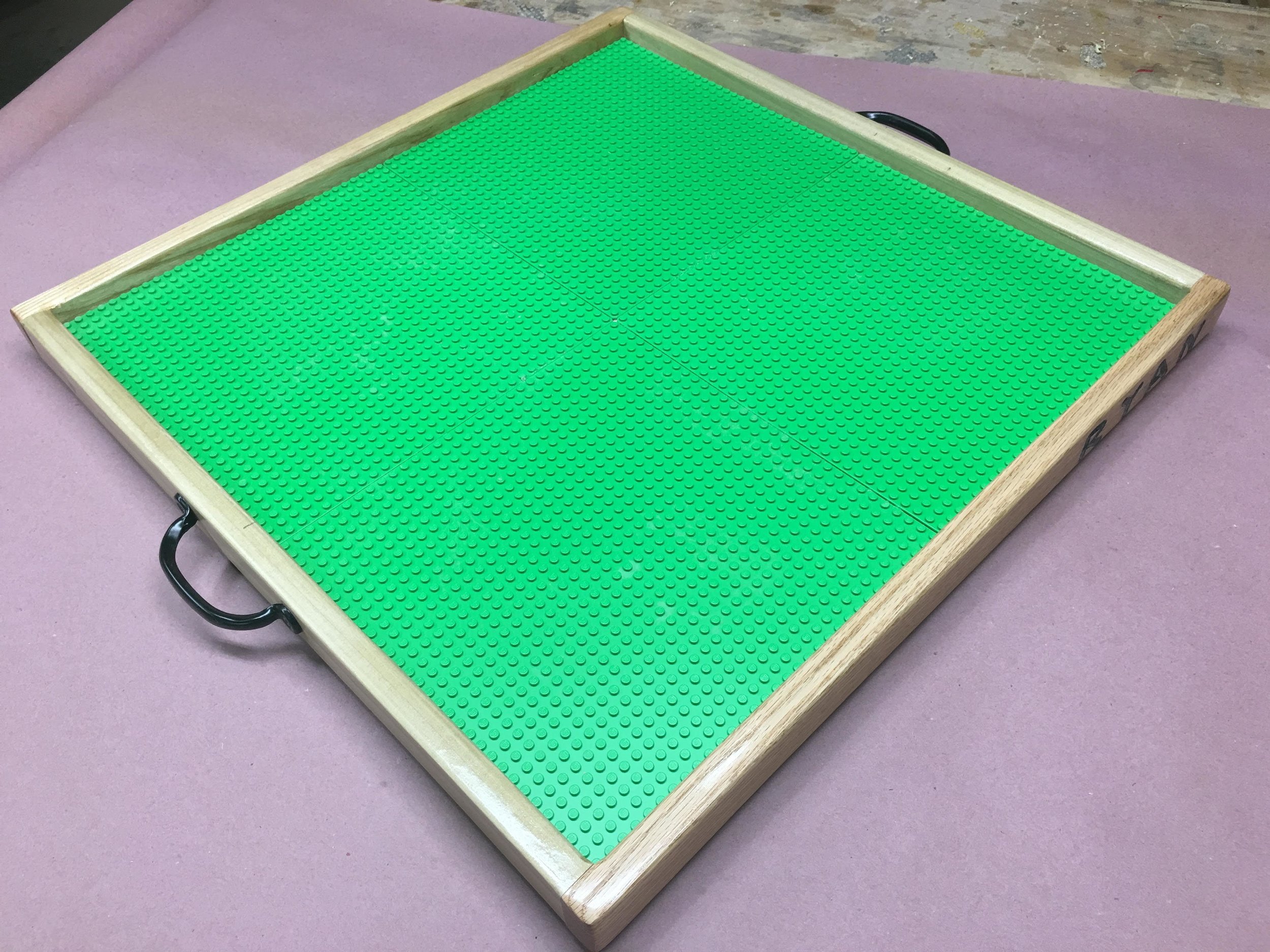

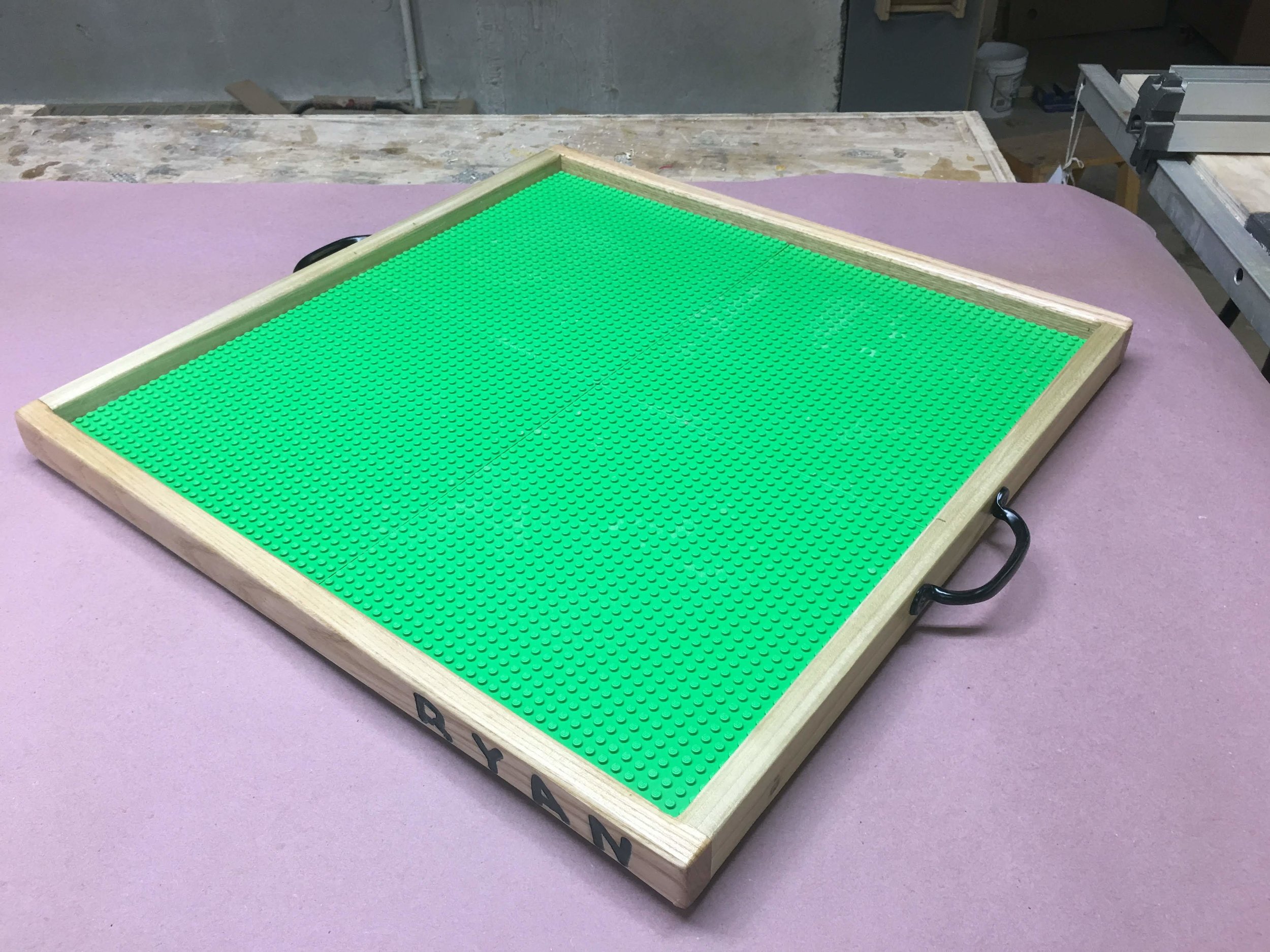

Lego Tray: All Finished

So today I finally put all the finishing touches on my sons Lego Tray and I have to say it came out better than expected.

HERE IS WHAT I DID

Some Sanding

More router work

Added Handles

Adhered the baseplates to the tray

Applied a finish

SOME SANDING

So after the paint had dried on the name I routered into two of the sides it was time to clean that up by sanding it, so I used 80 grit upto 320 grit paper to make the name pop. It isnt a bad job for some free routing.

Needed to sand the entire tray so I worked up from 80 grit to 320 grit for the entire tray.

BEFORE Sanding

AFTER sanding.. came out great

MORE ROUTER WORK

I also decided that I wanted to router a chamfer along the bottom edge of the tray to give the effect that it is floating on the surface. So I used a chamfer bit in my palm router and did all outside edges of the base.

Here is my palm router with a chamfer bit installed in the Colette

Here is a close-up of the chamfered edge as viewed from the bottom of the tray.

Here is a close-up of the camfered edge it really makes the whole tray look like its floating, I love this kind of subtle design element.

ADDED THE HANDLES

I wanted a simple way of carrying the tray around so I just purchased some big box style handles and attached them in the center of the frame components that didnt have his name routered in.

I had wanted to use handles that I made for a project during the summer that I had left over but they were too big to fit on the 1-1/2” wide sides of the trays frame, but these will do.

Adhered the Base-Plates

Unfortunately I didn’t get a chance to take any pictures of me doing this step because I had very little time in getting the gorilla glue onto the Lego base-plates and also the wooden base of the tray. The process was pretty straight forward I needed to scuff the bottom faces of the Lego plates and the plywood base so I used 60 grit sandpaper on both, this gives the gorilla glue a place to go to make sure I get a good contact between the 2.

Here is me using the 60 grit sand paper to rough up the bottom of the Lego bases plates

Here is me doing the same to the plywood base.

Next I used the gorilla glue to adhere the plates to the plywood and after they were fit in I used some heavy paint cans to weight down the Lego bases so as as that I got a good adherence to the plywood.

Next I added some felt pads to the underside of the tray that way it would npt mark the wooden floors if it go slid around.

Here is a picture of the felt pads.

Applied Finish

All that was left to do was to apply a finish and I had some oil based polyurethane leftover from the Beer Flight project I had just completed, I applied 2 coats today and that was it, all finished.

All Finished

Below you can see a slideshow of the completed project, this was a super simple project that anyone can make and it will provide hours of fun to children of all ages.

Thanks for reading this short blog and I will catch you the next time.

Lego Tray For my son

So my wife asked me to make something that my 5 year old son could use with his Lego and I wanted to make him one of those Lego tables with drawers but honestly had no where to put one so I did some research online and found this nifty little project where it is basically a tray that you can set on the floor and build on and when it is not in use he can just slide it under his bed.

I didn’t make any plans for this and pretty much made it on the fly using some scraps I had lying around the shop I did need to get some materials and they are listed in this post.

This project should only take 3 stages and Part one is below:

WHAT I DID TODAY

Purchased materials

Cut pieces to size

Pocket Holes

Router Time

Assembling the tray

Router Time 2.0

A little paint

PURCHASE MATERIALS

I went to my local big box store and Target o get some supplies and here is what I got

(4) Lego base-plates (10”x10”)

24” x 24” x 3/4” plywood panel

Gorilla Glue

I used scrap oak and poplar but you will need a piece of 1”x2” x 8” lumber.

(2) Utility handles

Pocket hole screws 1-1/4”

Furniture Pads

Here are all the supplies I got.

Here are the felt pads, screws and 2 handles.

CUT PIECES TO SIZE

In order to figure out what all the dimensions needed to be for all the parts and the plywood panel I needed to open all the Lego base-plates and get the overall size and it worked out to 20-1/8” square.

so I cut the 3/4” plywood panel to 20-1/8” square on the table saw, and then cut all the wood strips which make up the frame that surrounds the panel.

Here is the wood pieces getting chopped to final size.

Here is the plywood cut to final size

POCKET HOLE TIME

In order to attach the outside frame pieces to the base I needed to added a joinjery system so I decided to keep it easy and just add pocket holes so I just add screws to attach the sides while the glue sets up.

I use the Kreg K4 jig and made a station for it where all my accessories for the jig are stored. So I placed 4 pocket holes on each side, below you can see the finished panel and the K4 station.

Here is the finished pocket hole base

Here is one image of Kreg K4 pocket hole system that I used

Here is another image of the Jig

ROUTER TIME

I actually used the router twice in this build, I wanted to add my sons name to the outside edges of the frame so I used my Palm router to freehand his name but before I did that I needed to add some outlines of where I wanted to position the name.

Added outlines and even spaces of where I wanted the letters to go.

Using my palm router with a 1/4” upcut router bit to carve the letters in.

Next I used a sharpie marker to write the letters in, also gives me a visual guide when using the router.

Finally his name got carved, I will also adding black paint to the letters to make sure they stand out.

ASSEMBLING THE TRAY

I took the following steps to assemble the tray:

Added glue to the inside faces of the 4 frame parts

Assembled them in the clamping jig

Inserted all the pocket screws into their respective holes

Here is the panel all set up in the pipe clamp jig, just about getting ready to screw them home. Glue has already been applied to the inside face of the frame pieces.

Here is another image of pipe clamp set-up I used the clamps because when using pocket holes they have the tendency to move the work-piece as you are screwing the pocket hole screws home, this set-up alleviates that.

ROUTER TIME 2.0

I also wanted to add a round-over to all the edges of the frame so that my son didnt hurt himself on the tray, so I took it over to my router table with a round-over bit in the router and did all the outside edges, then I used my palm held router to get the inside edges of the frame and it came out great but tomorrow I will be sanding it down to make it even smoother to the touch.

Here you can see the round-over profile on the outside and inside edges of the frame.

A LITTLE PAINT

I wanted to add some black paint to the carved out letters for my sons name so I used some I had on hand and let it dry over night as I will be applying a polyurethane coat tomorrow. I will be sanding this whole surface down tomorrow which hopefully will make his name pop on the tray.

Messy looking right now but I will clean it up tomorrow.

HOW I LEFT IT!!!

Below shows a picture of how I left the project today

Here is the project as I left it today, more finishing work tomorrow

NEXT

Sand the entire project

Apply the polyurethane prob 2-3 coats

Apply the Lego base-plates using Gorilla Glue

Craft Beer Flights : On sale

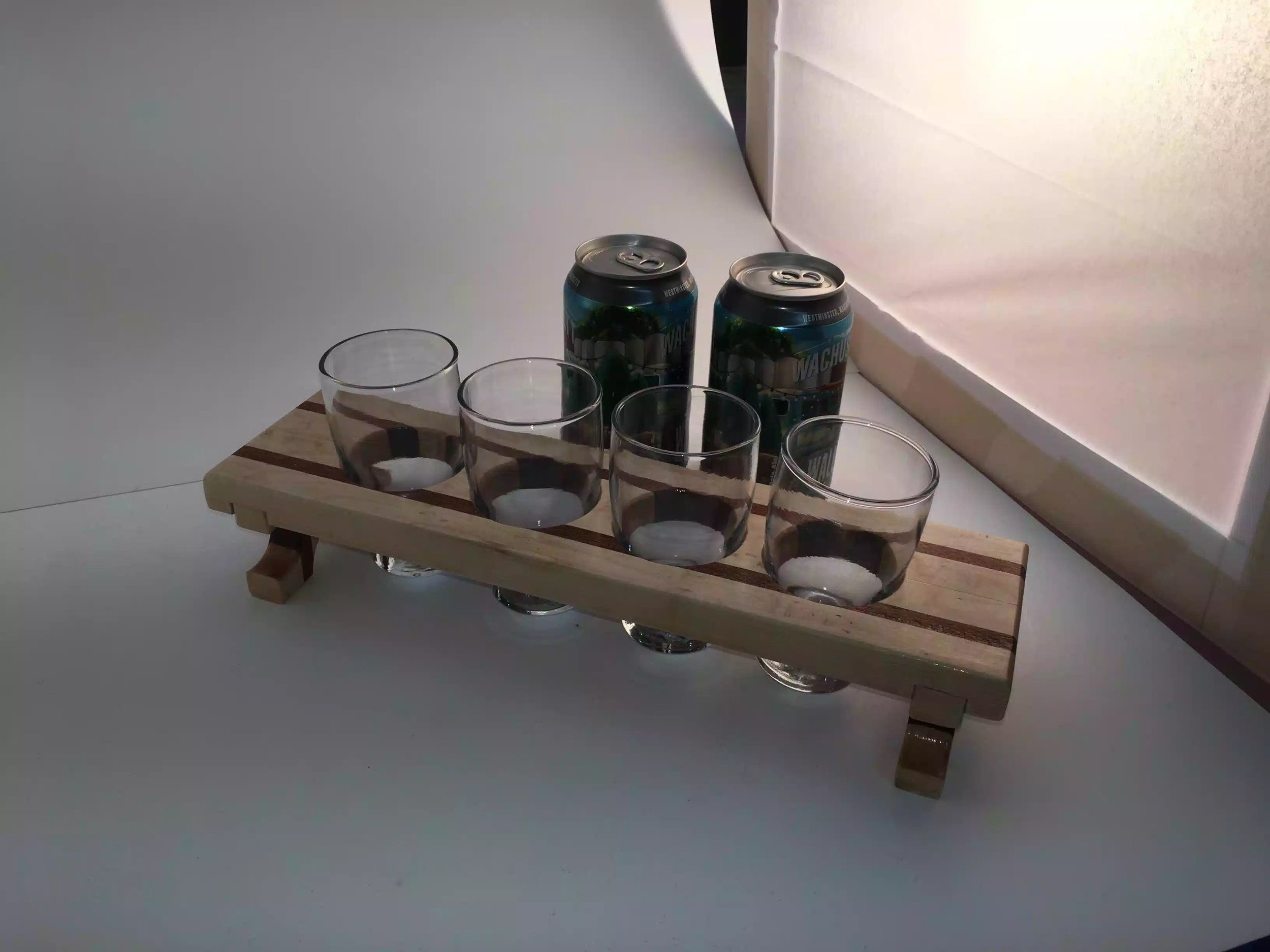

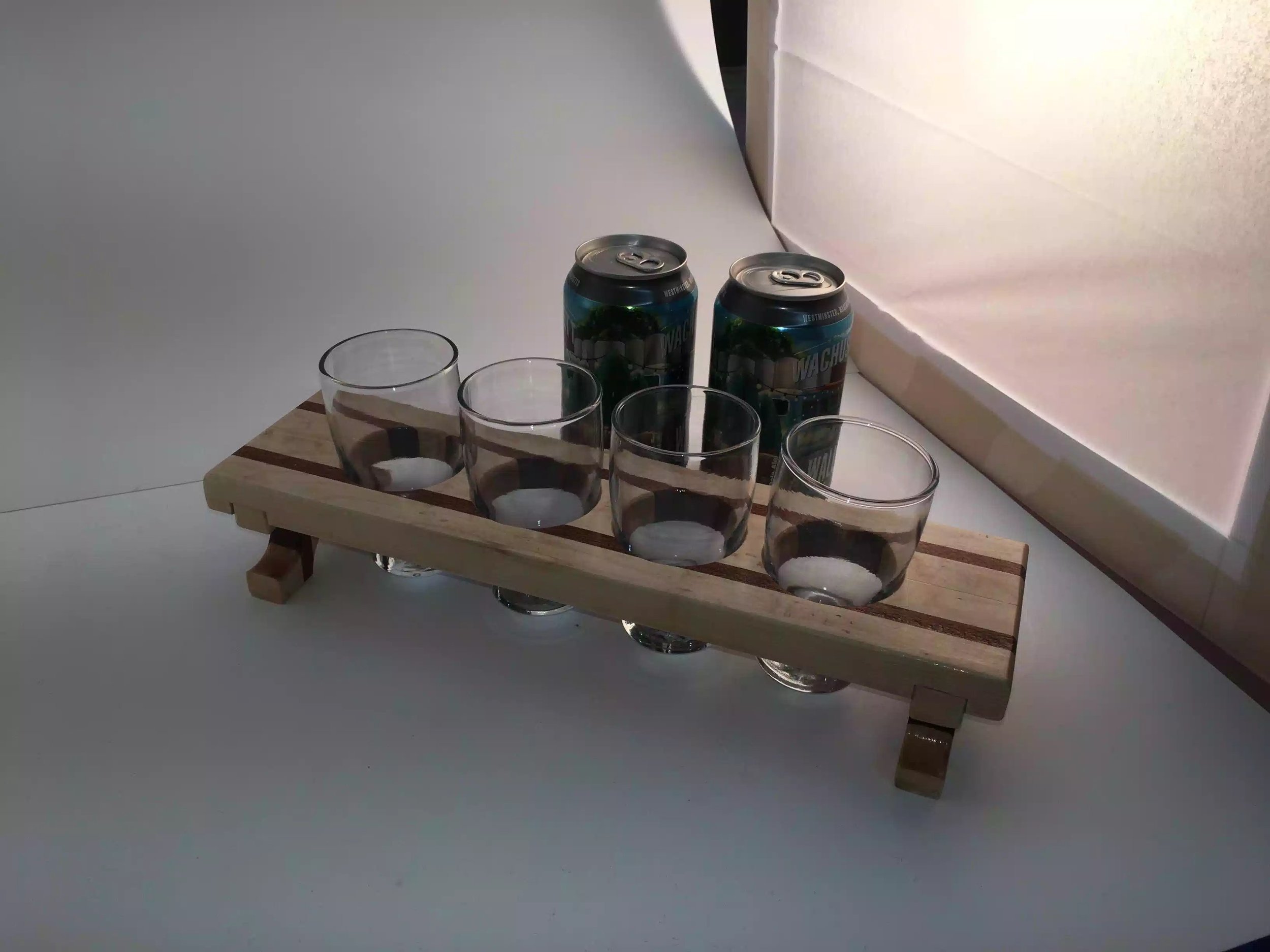

I finally got around to putting these beautifully hand crafted Beer Flights in both my Stores here on the site and also on Etsy.com.

These flights make a perfect gift for the craft beer lovers. I made two types that I will detail the differences below.

Craft Beer Flight : Design 1

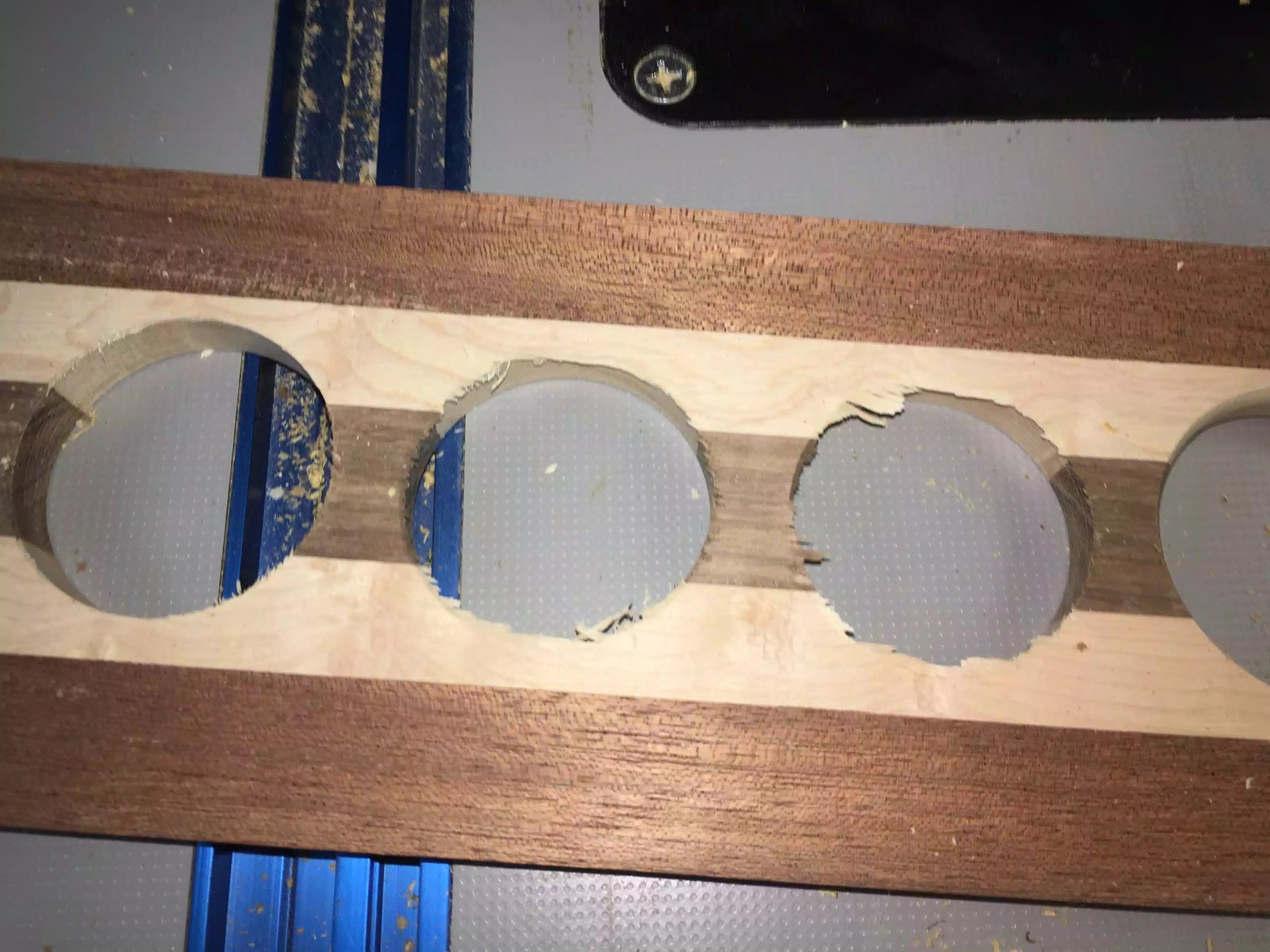

This craft beer flight is made up of 3 contrasting wood species. I used Brazilian Sapelle, Curly Maple and Walnut. They measure approx 13” x 4” x 2-1/4”. This set includes 4 glasses that are 5oz in size.

Craft Beer Flight: Design 2

This craft beer flight is made up of 2 contrasting wood species. I used Brazilian Sapelle & Curly Maple . They measure approx 13” x 3” x 2-1/4”. However this set does not include the glasses simply because I ran out, but the flights have 2” diameter holes that will fit a myriad of beer sampler glasses that are not hard to find, however if you really want this style with the glasses I am selling limited supply on my Etsy store.

I only made a handfull of these flights so if you like them snatch them up before they sell out.

PDF PLANS AVAILABLE

On the other hand if you would like to make these beer flights yourself I am also selling a complete set of plans that are on sale for only $10.00 in the store. I have put a link below.

Thanks for reading and have a great day.

CRAFT BEER FLIGHTS : FINISHED

So for the last couple of days I have been busy applying all the coats of poly 3 in total and sanding between each coat then finally I burnished each flight with very fine steel wool to remove that sheen that always appears when you use oil based polyurethane.

But today I finally got to take some pictures of the finished flights. I really enjoyed this project and loved working with all the types of woods that made up this project.

Below are some pictures that I took and one more thing I take such terrible pictures of my crafts I have actually starting using some photo editing software to see if I can improve my pictures to a degree that matches the woodworking craftsmanship that goes into make items such as these. The pictures I take for selling purposes are terrible and want to improve them. I purchased Paint-shop Pro 2019 and its a real learning curve for me having never used editing software again so I am studying and practicing and the picture directly below is a result of what I have learned so far.

Here is my efforts using PaintShop Pro 2019. Not bad but I have a long way to go.

Here is one style that I made using Maple and Sapelle woods

Here is the other style I made using Sapelle, Maple and Walnut

CRAFT BEER FLIGHTS : PICTURE COMPILATION

In the coming days I will be making these Craft Beer Flights available for purchase in my shop, I will let you all know when that is.

I will be taking a break for the month of December for the holiday period so I dont have any more projects on the books until the new year, I am going to be doing my anuual shop cleaning and trying to reorganize my shop for 2019.

Until the new year have a safe and happy holiday’s.

Project Award : Pipe Clamp Glue Station

A funny thing happened tonight as I was on www.lumberjocks.com website I realized that I was given a Daily top 3 award for this project and I didn’t even know it.

I made this station while I was very busy building and working on my Craft Beer flight blog series and to be honest I threw it together in an hour, took few pictures and moved on.

This is the 7th award I have received in 2018 and I have posted links to all things pertaining to its construction, including free project plans below.

Thanks Lumberjocks.com

Here is a bigger image of the completed station. Its very versatile and it can be completely broken down and stored away when not in use.

Craft Beer Flight : Part 6

Today was all about prepping for finish and applying finish to the flights. I chose to use a Oil based Polyurethane finish because of its properties to protect from moisture since we are adding beer glasses into the mix.

TODAY’S ACTIVITIES INCLUDED

Finish Sanding

Prep for finish

Before & After

FINISH SANDING

So before I could head into applying the first coat of the finish I needed to smooth all surfaces down so I used my miscellaneous sanding equipment which included:

Belt & Disc Sander

Random Orbital sander

Oscillating spindle sander

I used all these machines to get every surface smooth to about 320 grit.

I used Varathane Oil Based poly on the flights, I usually thin this out but because I need all the protective properties I didn’t this time.

Here are both styles of flights all sanded I have to say that I really love both and especially love all the contrasting woods I used.

Here is a close up the Maple & Sapele style

Here is the other style of flight with Sapele, Maple & Walnut

PREP FOR FINISH

So now that all my sanding was completed I needed to ready my work bench for some finishing work. I made my own finishing stands as the store bought ones were a little expensive, so I used some scrap plywood and and screws. They are super easy to make and whats also handy about them is that you can make a lot of different sized stands and they can be stacked as well. I have put some pictures below.

Here is a few stacked, makes storage easy. As you can see on one I have screws protruding through the top, this is what your work piece sits on while applying the finish.

Here is the top side of the stand, I used a forstner bit to drill a recess into the top that way the screw protrudes and allows each stand to sit onto each other.

Here are the stands in action, these are cheap and can be batched out how many you need and all you need is some scrap plywood and screws.

Next I needed to lay out all my flights onto their respective stands and go about applying the finish, as I said before I used an oil base polyurethane but I also used a foam disposable brush as I feel I get really nice finish using them.

Here are all the flights laid out on the rosin paper that I use to protect the work surface.

BEFORE & AFTER FINISH

Next I needed to add the finish and below you can see a few before and after pictures of the flights.

Before Finish

After finish, although the finish is still wet in this picture I really like how the finish brings the flight to life. I will probably use 2/3 coats sanding between each coat.

BEFORE FINISH

AFTER FINISH WOW… the finish as you can probably tell is still wet but really love the 3 contrasting woods especially the Sapelle on the outside edges.

Here is the how I left the flights today.

NEXT

I need to apply at least one more coat of poly and then I need to determine whether to add any more coats, I don’t want the wood to feel like plastic

Then they will be ready for sale.

Well that’s all I have for today, to be honest I am not going to document every coat I apply to the flights so the next post regarding this project will be the wrap up post, until then

Take Care & Thanks for reading

PS: I do need to start my monthly newsletter for November so if you would like to be added to the subscribers list please click here

Have a great Thanksgiving

From my family to yours, thanks for all the support and have a great Thanksgiving.

Kindest Regards

Ed

CRAFT BEER FLIGHT : PART 5

So today I got a little done, wasn’t a very busy day because of the glue-up.

TODAY’S ACTIVITIES INCLUDED :

Finished putting the dadoes in the flights.

The Glue-up

DADOES

I finally finished putting all the dadoes in the bottom sides of the flights. As I did previously I put a 1/2” dado stack into the table saw and raised it 1/4” high. Below is a picture of the finished flights, now that all joinery is cut so as that I glue in the sides and then its on to the glue up.

So all the flights are made all 9 of them.

THE GLUE-UP

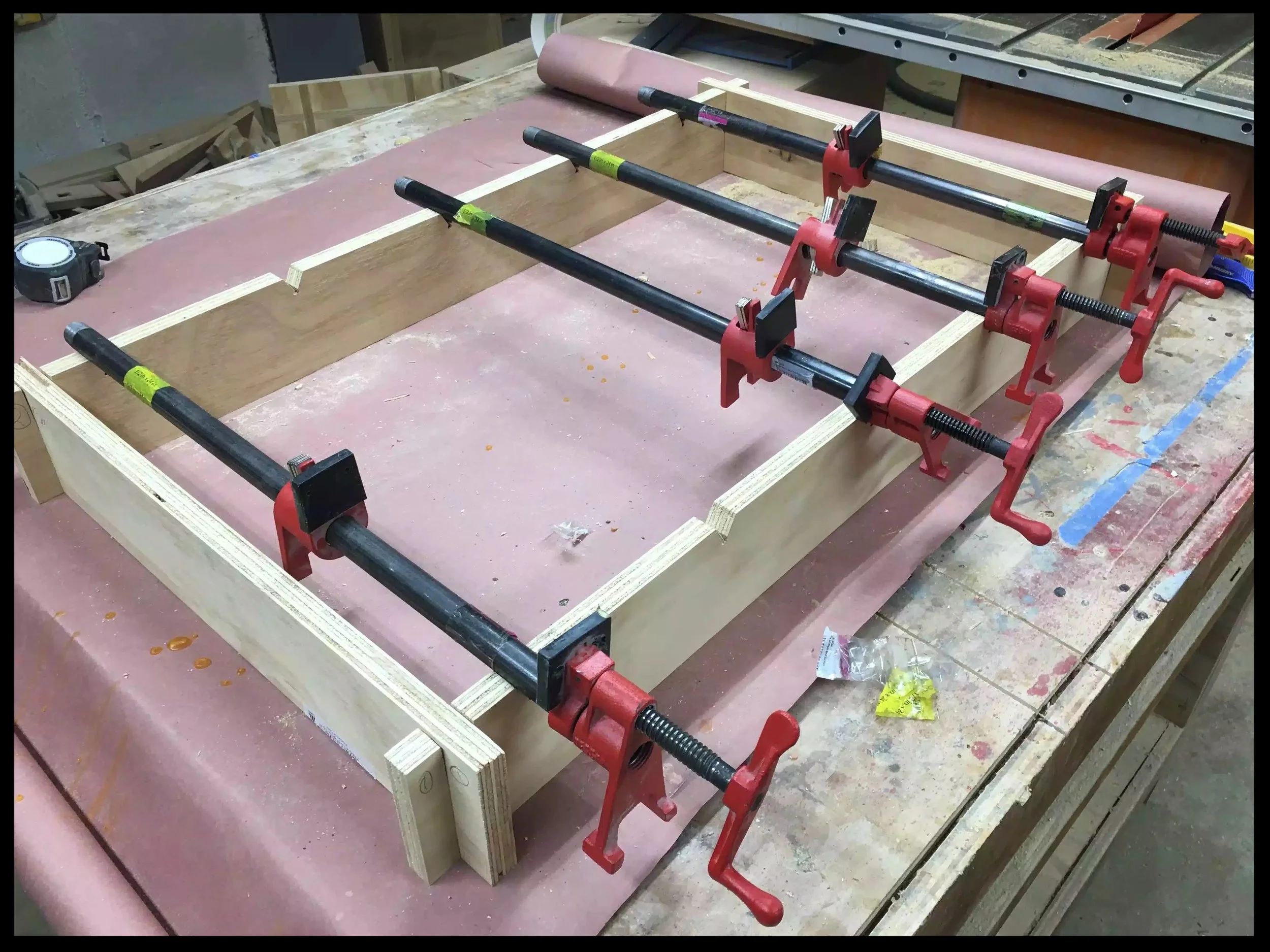

The glue-up was a lot of fun trying to figure out how I was going to glue up 9 flights at the same time with only 13 clamps. The glue-up consisted of just attaching the two feet into the dadoes I just cut.

My solution was to use the jig that I had just made for the pipe clamps . I used a brace across the pipe clamps that way I could clamp 2 flights back to back and only use 4 clamps for the bottom feet of the flight, then I used the rest of the clamps to secure the tops of the flights, its very complicated but here are some pictures to clarify.

Here you can see the pipe clamp jig with the braces stretching across all the flights, this way I could save on clamps and 2 separate clamps across both feet instead of using individual clamps for each foot.

Here is a closer look at the top clamps securing the front feet and bottom brace can support the back feet

Another close up picture

This clamping jig is really versatile otherwise I would have needed to buy a boat load clamps, I could fit 4 flights this way and the other 5 were clamped elsewhere using the back to back method.

NEXT…

I need to do one more finishing sanding and wipe them down

Finally I need to apply a couple coats of oil based Polyurethane.

Craft Beer Flight : Part 4

As I mentioned in the last part I had basically made 1 beer flight and today had a lot of rinse and repeat, and I am a man of my word. But there was also some other steps that I had started and will finish tomorrow.

TODAY’S ACTIVITIES INCLUDED:

Finish cutting all the glass holes

More Router Time

Oscillating Spindle Sander Time

More Sanding, but with my orbital sander

Creating the dadoes

CUTTING HOLES

Since I had only cut all the holes in 1 of the 9 flights I had to finish cutting all them holes. Nothing really new here as I documented this step in a previous part. Every Flight was to receive four 2” wide holes for the 5 Oz glasses to fit into. So it was back to the drill press to batch out this step. I did do one thing different and that was I gang cut two flight tops at a time. But to be honest I don’t think it was any faster because cutting two at a time seemed to bog down my little bench-top drill press and cant honestly say it was any faster.

Here is me starting to cut out the holes, it hadn’t dawned on me to start gang cutting them together yet.

After finishing all the hole cutting I had these little disc that I thought looked awesome and didn’t want to throw them away, not sure what to use them for YET!!!

Here is all the holes finished, next I needed to bring all these piece to the router table. This picture is of the maple and Sapele flights.

Here is the other style, I was very careful to match all pieces in order of me cutting them so as that the grain matched on the whole piece once glued up.

ROUTER TIME

As I also did in a previous step I ran the flight parts through a 1/4” round-over profile bit in the router, I like the look of round-overs and they also feel great to the touch. I spent a decent amount of time doing this as I needed to do 8 flight with 3 parts that is a lot of routing, but they did come out awesome.

Here is a picture of the flight top and I used to round-over the inside edges of the holes and I also rounded over the top face of the flight.

This picture shows all pieces after the round-over has been applied to the edges.Next is sanding

Here is a close-up of the top with the round-over profile applied.

Here is what the sides look like with the round-over applied.

OSCILLATING SANDER TIME

Now that I have completed all the router work on all the pieces it was time to get rid of the tool marks left behind by the router bit, to get all the curves I used my spindle sander and this is an awesome tool, its not a multi-function tool but all the same it is very good at sanding all them circular shapes in the wood and it will takes the finishing touches up a notch.

Here is my WEN Oscillating Spindle Sander, this tool is a real joy to use, I used my 1” diameter sanding sleeve to get into all the curves, I could have used a 2” sanding sleeve but didn’t want to replaced all the sleeves as that would have been time consuming, anyway the narrower diameter fit very well into all the curves I had.

MORE SANDING:ORBITAL SANDER

Now that all the curves were sanded it was time to sand all the faces and edges of the parts and to do that I used my orbital sander on a non-slip mat because most of the part’s were very small and I needed to keep them stationary. I started with 100 grit sandpaper on the sander and finished with 320 grit and all the parts were very smooth to the touch.

Here is a image of my sander and the non slip router mat but I use almost all the time when I need to sand something that is very small and clamps and vises are not the best options to hold down the work-piece

DADO TIME

Now this is a step that I didnt do before and that is creating the dado groove to receive the feet on the under side of the flight top.

I put a 1/2” wide dado stack into my table-saw and raised it to a 1/4” high as that was the depth of the dado, I measured 1/2” from each side so as that when the glasses were in place they didn’t interfere with the feet or sides.

Here you can see the feet sitting in the dado I just cut, the dado groove runs the entire width of the flight, I have to say that it looks great for a simple joint and it is also extremely strong.

Here is a close-up of the dado joint, fits like a glove.

Here is where I leave it for today, this is a picture of one of the flights done, just need to be glued up.

Here is how I left 1 of the flights , tomorrow more rinse and repeat.

That is where I leave it for today.

NEXT:

Finish cutting all the dadoes

The Glue up

Applying the finish.

Thanks for reading and I will catch you next time.

Craft Beer Flight : Part 3

So this morning I had a pretty productive day until my drill press broke but I fixed it. I had a decent amount of work to do but only had half the time I usually have, but I still declare it as a productive morning.’

TODAY’S ACTIVITIES INCLUDED

Finished some surface Sanding

Cut parts to size

Some Layout

Drill Press Time

Crisis

Holes all cut

A little routering

Happy so far

SANDING

After doing all the hand planing yesterday I had very little to do with my random orbital sander, I started with 120 grit paper and finished with 320 grit and I was very happy with the feel of the wood. After all the events of the past two days of gluing up and ripping wood I now finally have 3 lengths of wood that I can now turn into 2 styles of flight.

Below you can see the lengths of wood all ready to be chopped into individual flights.

Here ate the 3 pieces of wood all ready to be chopped up.

Here is the soft Maple & Sapele wood style

Here is the Soft Maple, Sapele & Walnut style.

CUT PARTS TO SIZE

Using my plans I cut all the pieces to final length and made sure to cut the pieces in sequence so as that grain wrapped all around the flight adding that little visual interest if someone was looking at it closely.

I set up my miter station so as that I didn’t have to measure the work-piece every-time I needed to cut it. So I made some pre-dimensioned spaces to use for each size cut.

Here is the work-piece on my chop saw with the spacer, there was a decent amount of cuts and they all came out exactly as I wanted.

Here is a close-up of the spacer.

Here are the 3 parts came out the exact dimensions I wanted.

SOME LAYOUT

I needed to do a little layout on the parts mainly because I was cutting so many holes in the 3 parts and I needed to make sure all the cuts were in the right places.

Using my 3D plans I used this to determine where to make my layout marks especially on this piece as there is 3 half-circles to be cut.

I used my combination square to mark the center points of where the holes that would hold the glasses were to be cut.

DRILL PRESS TIME

Most of the cutting and shaping in this project will be done on my bench-top drill press using 3 different diameter hole saws, doing half-circles on the bench-top cause a few problems which I encounter and also their solutions

Make difficult cuts on a small sized work-pieces

My solution to this problem was to enclose the work-piece on all sides so as that that both sides of the half cut were supported and didn’t pop out and also very importantly was my fingers were no where near the cutting edges of the hole-saws.

Keeping the parts orientation the same on all parts while cutting

I used a system of little fences surrounding the work-piece so as that the work-piece didn’t move while I was cutting out the 1” diameter half circle

Here you can see how I surrounded the work-pieces I used scrap wood and double sided tape to secure the pieces. Worked great

Here is an image of me starting to cut the large glass holder holes.

Obstacle using the hole saw.

One of the problems that I encountered using the hole saw was that the hole saw had a drill bit centered inside the hole saw and that proved difficult in centering the hole saw on the work-piece, but what I didn’t realize was that it could be removed. You can see the drill bit in the hole saw below.

As you can the drill bit in the center of the hole saw is there to make sure that cut is centered, but was easily fixed as it unscrewed from the saw.

CRISIS

Right when I started cutting the little side holes my drill press had broken, the entire chuck came off the drill press, but it was an easy fix after watching some YouTube video I had it fixed in under a half an hour. I think what happened was that the chuck was never properly seated on the arbor so I tapped the whole chuck onto the arbor and so far I have not encountered any problems, below you can see the chuck still attached to the hole saw.

Here is the chuck, thank god for YouTube and some quick thinking on my part.

HOLES ALL CUT

After most of the morning cutting holes and layout all six of my beer flights have sides completed I need to finish cutting all the glass holder holes . But as you see below they look pretty good. I did get a little tear out on the big holes but I cleaned all that up on my spindle sander. In my next step I will also add them through the router with a round-over bit and that will clean them up even more. There are some pictures below

Here is the top before finish sanding

Here are all the parts before I got to sand them, I used my spindle sander to clean them up.

ROUTER TIME

I wanted to add a little profile to all the edges as I think it gives them that polished look and a nice professional look. So I used my trusty router table and 1/4” round-over bit and routered most of the edges of the pieces. I needed to be very careful with the small side feet as it wouldn’t take much to blow out a piece of the sides.

Below you can see the finished profiled edges.

Before routing

After Routing,

Here are all 3 pieces routered and I have to say look great, I also added the same profile to the top side of the large flight piece but I didn’t do the bottom face as I will need to add a dado groove in there next.

Here is a closer look at the profiled edge on the top piece.

ALMOST DONE, BUT NOT QUITE YET

Although I still have to glue the legs in and cut the dado grooves on the underside of the top I needed to see what they look like all assembled , I also needed to make sure that the glasses all fit, so here are some images of them pre-assembly

So that is what I got done today, I still have a good bit of repetitive work as I am making 6 of these. But so far so good.

NEXT

Cut Dado grooves on the underside of the top so as that I can glue the feet on.

Rinse & Repeat on the other 6-8 Flights

Apply finish

ALL PLANS $10

Get any of my plans now for only $10 !!! This sale is only for 30 days.

Craft Beer Flight : Part 2

So today marked the second day of the project and before I could get started on a side project and that was a Pipe Clamp glue-up jig and I created its own blog entry and you can find it in the link below.

TODAY’S EVENTS INCLUDED

Started to clean up the dried flight blanks that I did yesterday

One more glue-up

PIPE CLAMP GLUE-UP JIG

I wont go into too much detail on this as I created a project blog detailing the build, but I will say this. After yesterday’s glue-up I was very frustrated both during and after . Glue-ups need a good system and a little rehearsal because my system was flawed it didn’t matter how much planning went into it, it would never be a pleasant experience.

I had researched making this some time ago but it was always put on the long finger and put onto my to-do list, which I never got to do. But because this project had a lot of different parts in gluing it up I tried a method that didn’t work and decided before I move one more step in the current project I needed to get this done.

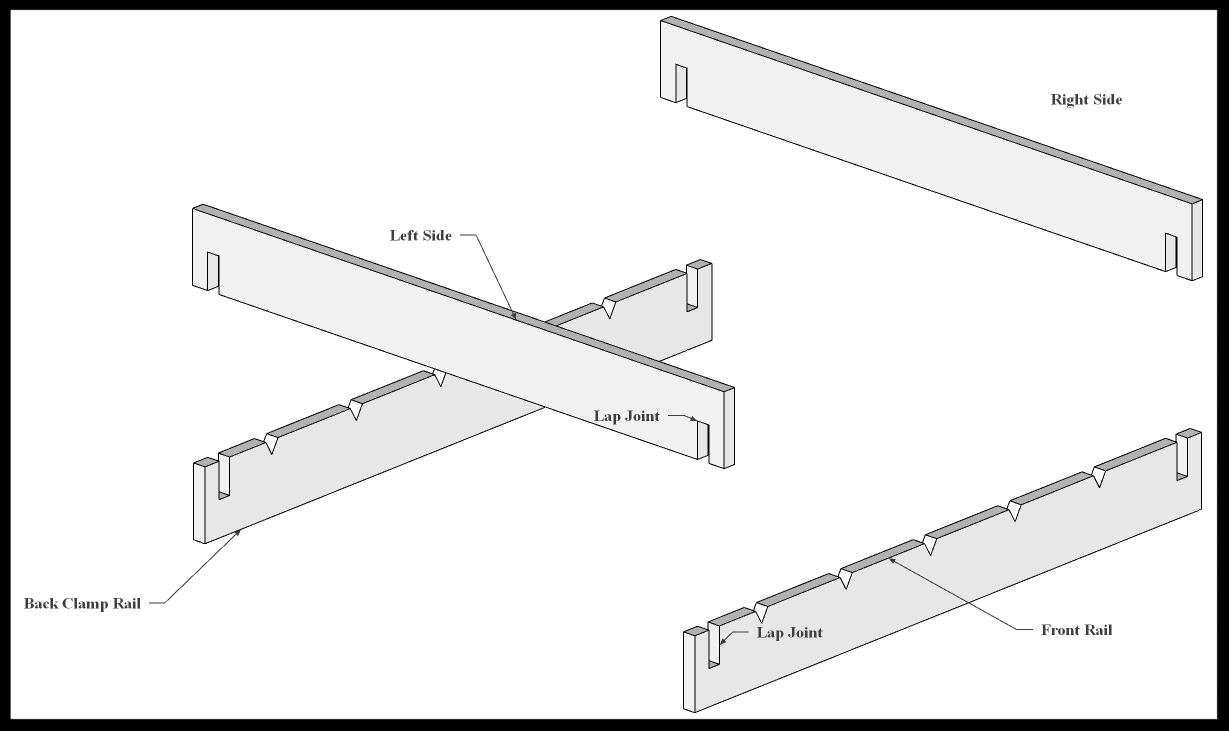

Anyway the project is super easy and if you have scrap plywood lying around it will not cost anything to make. Its basically a jig that has a front & back with 2 two sides. It can be broken down and stored away when not in use.

Below is the finished image of the jig, but [please feel free to go over to the blog entry for more details, the link is below)

Here is the finished clamping jig

BLANK CLEAN-UP

The boards needed a good bit of clean-up , and the blanks developed a bow in the middle so I tried to address this by turning the 5’ sections on there sides and trying to level it by running it through the table-saw blade, I really dont recommend doing this as it unsafe. But since I don’t have a planer or joiner I had to try something. It came out OK but tomorrow I will need to use my belt sander with some course paper to true the face up a little more.

Below you can see how I left it today

Here is the blanks as I left them today, I have some wood burn to clean up and then start turning these in beer flights, the fun stuff.

ONE FINAL GLUE-UP

The last thing that I wanted to get done today was to glue-up that final blank that I could luckily make after realizing that I had enough scrap pieces left from yesterday, I came up with a flight that is a little narrower but had maple & sapele woods that I could turn in another 2-3 flights.

Another bonus was that I could get to use the new glue-up jig that I just made and man o man was it a much better experience and hopefully will result in a much flatter glue-up than yesterday’s.

You can see some pictures below.

Here you can see the different design in the clamping jig. Most of the blank is maple with 2 contrasting Sapele pieces on each side.

The jig worked an absolute charm

Another picture of the jig in action.

Well that is what I got done today, thanks for tuning in and I’ll catch you again later.

NEXT……..

Clean up the blanks with some sanding and make sure they are true and flat

Hopefully I can start cutting the blanks up so as that I can move onto the next step, layout.

Pipe Clamp Glue-up Station

So after yesterday’s glue up fiasco I decided today that I would make a clamping station, something that I have been meaning to do for a while now and I will describe the project below.

Research

Materials

Design

The Build

RESEARCH

I found 2 articles online that I used to design this jig, one I found on one of woodworking pages that I am a member of and the other was a YouTube video, links to both are below.

I really liked this concept because of a couple of reasons.

It was quick to make

I could use scrap plywood, so it didn’t cost anything

I could collapse the jig and store until I needed it

I could customize it, I could make any length I wanted depending on the usual size of glue-ups I do, I could also make different sized stretchers depending on what size clamps I would be using.

The other resource that I found was a YouTube video created on a channel called the Woodworkweb and you can see it below.

This guy took a different approach to how the pipe clamps would be secured into the jig, instead of using the half-circle approach , he thought that there was still too much movement when the pipe clamp was sitting on the jig so he created a “V” so as that the pipe would be more secure inside the jig.

He demonstrates this in the video below.

MATERIALS I USED

I decided to use scrap plywood that I had on hand and I couldn’t think of a better project because I could clear some of my stock.

I had a quarter sheet of plywood, so the dimensions I used was 4” high x 40” long piece for the front and back of the jig. I also made 2 different sized stretchers or sides of the jig so as that I could use different sized pipe clamps depending what I was actually gluing up, so I made the stretchers 24” & 36” wide.

DESIGN

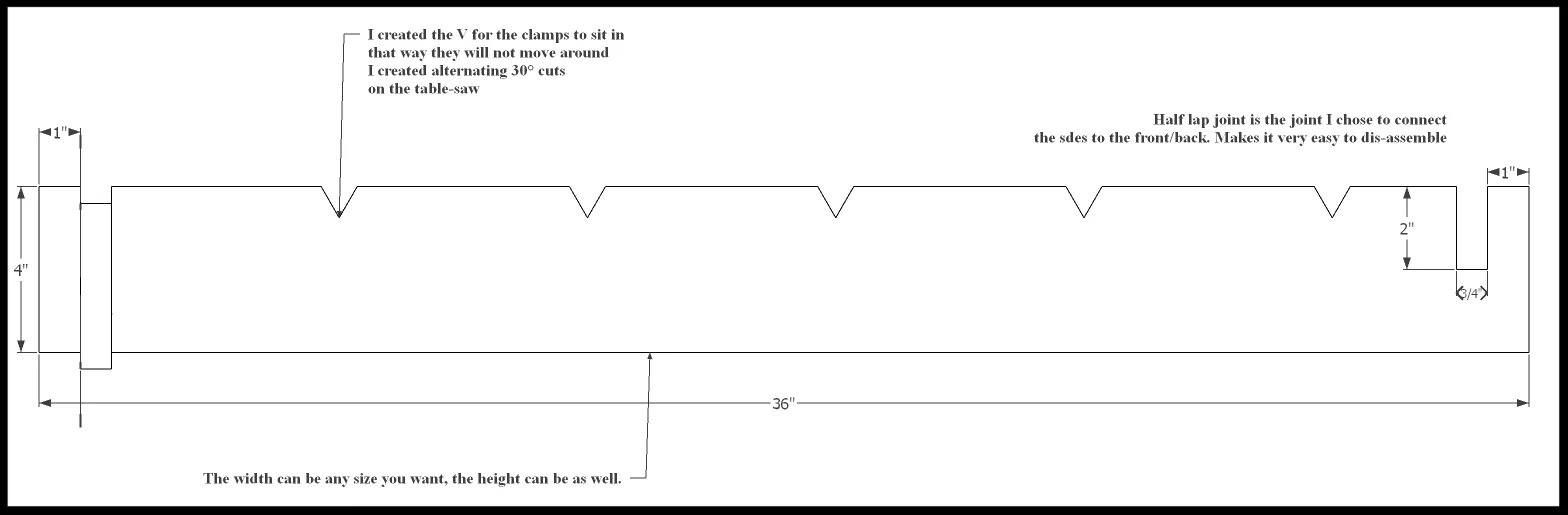

I turned to my trusty Sketchup to design the 3D Version of the jig. You can see some pictures of the plans that I made below.

Here is the finished design.

Here is the front & back clamp rail, the front & back are mirror images of each other, you can see the V cutouts that I made and the guy is absolutely correct the bar clamps do sit more securely in the jig.

Here is the side , again each side is the exact same as each other, and the only thing you need to do to them is create the half-lap joint that creates the joint to secure them to each other, it is also what enables the jig to disassembled and stored away. One thing to note is the sides has the bottom part of the joint cut and the front/back has half-lap cut into the top part.

Here is an exploded view of the jig, you can kind of see how the parts fit into each other.

I included a link to the free plans at the bottom of the post.

THE BUILD

STEP 1 : I cut the plywood to size which was the following

2 Pieces at 4” wide x 36” (front & back pieces)

2 Pieces at 4” wide x 36” (sides)

2 Pieces at 4” x 26” ( these will be used with 24’ pipe clamps)

STEP 2 : I marked out where the half-lap joinery needed to be placed so I measured 1” from each side of the front/back parts then using a piece of scrap of plywood marked the position of the lap joint. To avoid making any mistakes mark out the waste for the lap joint ,on the front & back the lap should be removed from the top. The side pieces should have the material removed from the bottom. I could of used my dado stack in the table saw to remove the half-lap waste but 4 only 4 cuts I decided to just leave the regular blade in the saw and clean up with a chisel.

STEP 3 : I needed to add the “V” notches to hold the bar clamps in place.

To do this I tilted the saw blade to 30° and lowered the blade to about 3/4” high and made a pencil mark on my miter fence to determine where the starting point of the blade entering the work-piece and then made another adjacent mark about 7/8” away from the other, this marked bot sides of the cut, thus creating the V. I spaced out each V about 5-1/2” away from each other and I got this measurement by laying out 2 bar clamps next to each other to determine what space I needed so as that hat the clamp handles could rotate freely to tighten the clamp without bumping into each other.

Basically that is all you need to do, I posted pictures below to show some of the features of it and I actually got to use it today for another Project that I am working on “The Craft Beer Flight Project”

Here is the finished jig.

Here is a close-up of the half-lap on the front part of the jig, you can also see the V notched in

Here you can see how the clamp sits in the V notch and it works awesome

Here is one of the sides with the material cleared on the bottom of the joint.

Here you can the side piece with the completed half-lap material removed.

Here is how the half-lap works its an extremely strong joint.

Finally the jig in action, I should have made this a long time ago.

So now that I have solved my glue-up problem I can move back to my main project. I hope you enjoyed this little project, its not the fanciest project but it sure is a functional one.

Craft Beer Flight : Part 1

So today I started making the craft beer flights and boy was it a messy start, mainly because I needed to do pretty big glue-ups. They were not widest glue-ups but they sure were plenty long, anyway more about that later.

Today’s Events Included:

Ripping all the wood on the table-saw

My Designs

Glue-up Prep

Glue-Up

Ripping the wood

So I needed to take all the wood and cut them to the dimensions that I made on my plan, I ultimately wanted a 4-1/2” wide flight and using 3 species of wood which were Sapele, Maple and Walnut. So I needed to take these boards and cut them into smaller strips.

so I installed a rip blade in my table-saw and also placed a feather-board in place so as that the wood piece would move while I was ripping it.

Here is the table-saw set up I made with the feather-board in place

Here is the 3 species of wood that I will be ripping.

Here are all the pieces ripped and came out great as there was no burn marks on the wood as I used a rip blade.

Here is another close up of the boards that were just ripped.

My Designs

So here is the design I came up with I really like the contrasting woods and should come out great, I was lucky enough to make another design by some of the leftover off cuts that I had.

Since I had more maple and sapele left over I could make this design as well its really nice as well. So what started out as making 6 flights I will be able to make 8-9.

Glue-Prep

The glue-up was going to be a little complicated because I wanted to glue up three 5 foot sections all at one time. I wanted a system where I would clamp all three together with dividers between each of the glue-ups and that way I would not need a ton of clamps, but that turned out to be not the most efficient way and I didn’t get one of the glue-ups done. I was using Titebond II and the open time was not long enough to fit in 3 glue-ups so I just did 2.

I really dislike the method I used and really need to rethink my process, I use 3 pieces of plumbing white pipe on top of wooden risers as you can see in the picture below, and the dividers that I used to separate each glue-up were different heights so I couldn’t use clamping cauls, I will know more tomorrow after the glue has set but I think I am going to have a fair bit of surface sanding because I don’t have a planer.

I also had to make a trip to the local big box store to purchase more clamps as the clamps I had were too short so I got the Bessey Pipe Clamps and a couple of 24” black pipe pieces. After I finished for the day I started researching better clamping set-ups If my shop was a little bigger I would just make a clamping table but since that is not possible I found another method which is portable and can be broken down and stored away when not in use. I think I am going to make this tomorrow and probably make a few different rail sizes depending on what size clamps I will be using at any specific time.

As you can see its a front and back rail with stretchers on either side, he notched out half circles to accommodate the pipe clamps, The stretchers are help together using a half-lap joint and when not in use can be just pulled up and the jig can be stored away.I think I will make mine the same but I will add different sized stretcher depending the size of clamps I will be using, they usually range from 12” - 36”. Click here for the website I found this on.

Here are the white PVC pipe that I have nesting in some scraps, but didn’t work great because the scraps kept falling over.

The idea of the white pipe was that it gave the work-piece a flat surface to sit on, and it also afforded me to add height to the glue up so as that I could place clamps on the bottom and top surfaces of the work-piece.

Here is the final pieces with all the glue applied, I will not be doing this again. But we live and learn.

I really do like the patterns on the flight and think they will be really nice when finished.

That’s all I got done today and thanks for reading.

NEXT

Build the pipe clamp glue-up jig… I might need to get some plywood but I am not sure if I have enough scrap to get this done.

If I have enough time I need to do some surface sanding on the 2 glue-ups I got done today and I would like to get the other glue-up completed hopefully using the new jig.

Craft Beer Flight : Prototype

Some times its beneficial to make a prototype of the project that you eventually want to make especially when you are marrying 2 elements together, most of the time on a project this size its not always necessary but I had to many unknown measurements especially considering putting glasses in the flight, and also it helps to have a tangible object in your hand to see any design elements that might look great on a computer but look bad on a finished project.

Below are the steps I took to make the prototype:

I used plywood to make the prototype as I had some on hand, but really any material could be used to make it. So my first step was to cut 3 pieces of plywood to my dimensions for the beer flight, a top and 2 sides

Next I had to do some layout

Cutting the circles & Circle cutting tools

Cutting the dadoes

Router Work

A little assembly

THE PARTS

There are only 3 parts to the beer flight, the top and two sides. Below is a picture of the plywood parts, when I actually get to making the flight I will be using 3 species of wood that I will need to glue up but I don’t have to do that now and this prototype project only took me like 90 minutes to make.

Here are the parts, the back pieces are the sides and the front piece is the top of the flight.

SOME LAYOUT

There was quite a lot of layout work in the design phase of this project, so I took all my dimensions from Sketchup and that was one of the main reasons I am making this prototype. Here are some of the dimensions that I needed to layout

Centering the holes for the glasses on the flight top, making sure to keep clear of the left & right legs that were underneath the top. So I measured 2-3/4” from each of the sides (left & right), the second measurement was 5-1/4” repeat that measurement as i did on the first. I also need to draw a centering line 2-1/4” from the top edge and where these lines intersected was the center hole I would use my hole saw to drill out the piece (more on that later)

Next for determining the center hole for each of the 4 holes that will be cut for the glasses. I needed a 2” diameter for each hole and I also wanted a 1/2” space between each of them holes. This was another reason for the prototype because I wanted to make sure that the 1/2” space was enough so as that the glasses didn’t bump into each other as the style of glass I was using had wider top than bottom.

Next piece of layout was for the feet mainly because I was cutting 3 half-circles into each piece. A half circle was to be cut halfway up the left & right side of each foot and that hole diameter was 1” and one half circle on the bottom and that diameter was 2-1/2” wide centered on the foot.

Here is the layout done on one of the feet.

Here is he layout on the top piece, I also drilled pilot holes for the hole saw to track correctly.

Here is the layout for the dadoes, I measured 1/2” from each side and drew lines indicating where I wanted the dado to go, that’s later.

CUTTING THE CIRCLES & CIRCLE CUTTING TOOLS

So since all of my layout lines are in place I needed to actually cut the circles that I incorporated into the design. I used three different diameter hole saws (1”, 2” & 2-1/2”)for this and I also used my bench-top drill press doing this, you could use a handheld drill but it would be difficult especially on the half-circles.

I used my Milwaukee Hole saw set as it had all the circle saw diameters that I needed, what a great tool even in a under-powered drill press like mine.

Here is a close-up of the 2” diameter hole saw.

Here is my current drill press set up, if you would like more information on how I made the drill press table or drawer cabinet you can find more information here.

Cutting the circles started with me cutting the 2” diameter holes in the top, I needed to cut 4 of these as they will house 4 glasses.

Here is the work-piece positioned under the hole saw, the work-piece was turned end for end to get both left and right sides done, the saw did a great job as I didn’t get any burn marks on the work piece.

Here is a close-up of the circle cut-out.

Next I needed to cut out all the half-circles in the feet and I needed a method that would not waste any of the wood I have, So I came up with a method on the drill press that allowed me to cut the feet to exact dimensions not bigger, sure I could of made an overside work-piece and drill the full circle out and cut the circle in half but that meant wasting wood.

So the method I came up with was to use 2 sacrificial plywood scraps to go either side of the the work-piece which were stuck in place with double sided tape on my drill press table and support the entire cutting edge of the hole saw and when I was finished I could put another work-piece in place and repeat until my sides were milled.

also another thing to note that the feet had 2 different diameter half-circles to be cut if you remember from my layout.

Below are some pictures of the process.

Here is one of the sides in place and to the left and right are 2 sacrificial pieces, he idea was to make sure that the entire cutting surface of the hole saw had something to drill into , thus keeping the hole saw tracking in the downward direction and not chewing up the main piece, and it worked out great. This picture shows me drill the 1” diameter holes on the sides of the feet.

Here is another shot showing all the holes drilled out.

Here is a close up of one of the sides. Came out great

CUTTING THE DADOES

The joinery method I will be using to join the feet to the underside of the top will be dadoes. These are just grooves that I cut out at the table-saw with my dado stack, the width of the dado stack is determined by what thickness wood you are using. I measured 1/2” from the left and right side.

The other main reason I was doing a prototype was because I wanted to make sure that when the glasses were sitting in the flight that they didn’t interfere with the feet in any way, and thank god I didn’t.

Here is the bottom face of top and you can see the 3/4” wide dado that is also 1/4” deep into the top.

ROUTER TIME

Finally I wanted to add some decorative elements to the flight so I used my router with a 1/4” round-over bit in the router to clean up all the rough and sharp edges left on the outside edges of the parts, I also wanted to add a round-over to the inside edges of the holes where the glasses will be sitting.

One thing that I might change is using either a different router profile bit for the edges on the top, or just using a 1/2” round-over, but I need to think some more on that.

Below are some pictures of the round-overs that were applied.

Here is the round-over profile added to one of the holes on the top. This will look a lot better when its actually wood.

Here is one of the feet rounded over. I like the look of it and don’t think I need a larger bit.

Here you can slightly see the round-over to the top, its very faint that is why I am thinking of using a larger round-over bit , or perhaps even a roman ogee profile might look better, food for thought.

ASSEMBLED PROTOTYPE

I am so glad that I made this prototype and got most of my questions answered and happy to realize that all of my dimensions were correct, although it will take a decent amount of time in fabricating the feet I think they are worth it and really think they will look great in the woods that I will be using.

I also like how the transition from the feet into the top is really nice and love the look of the very visible dado that will attach the feet to the flight. The only thing that I am questioning is the width of the flight top which is 4-1/2” wide, thinking possible that is too wide for 2” diameter glasses, so maybe after-all I will be adding a larger round-over profile to the top which will eat away some of that 1” on the front and back edges of the flight.

Below are several pictures of the finished prototype, I hope you like.

Frontal picture showing the glasses in there homes, there is about 1” clearance from the glasses to the table-top. Love the dado joint.

Here is the top view, 1/2” gap is perfect.

Here is the side foot, I think this is my favorite aspect of the prototype, really like the curves.

Even in plywood the dado joint looks awesome , imagine what this will be like in the real deal.

NEXT:

I will be starting the build. Hopefully I will catch you guys later.

New Project: Craft Beer Flight

INSPIRATION

I have been wanting to make one of these for some time now and I figured now would be a good as time as any, and they make a great gift. My last project was a success but to be honest I am a little worn out making Trivet’s but this is why I love woodworking as a hobby mostly because I can pick and choose what projects to make and when.

In my spare time as rare as that is, I love frequenting local craft beer breweries and when I first went to one about 2 years ago I was amazed at the quality of beer that was being made in the same town that I live, love IPA’s. Anyway craft beer breweries rotate their selection very often and since they do that you are never sure which one to try next and that was when I introduced to my very first beer flight, which is usually a selection of beer samples that are usually 5 ounces and they also arrive on a wooden paddle that holds the beers in place, well that is what I am going to make.

SOURCING THE PROJECT MATERIALS

Usually when I want to make a project I have a process that very rarely changes and are usually performed in this order

Inspiration (Research)

Design (Sketchup)

Source Materials

The build

But this time was different I went to the lumber yard at Barney & Carey before I even designed a model. Some of the wood that I wanted to use was species that I never used before and therefore didn’t know how much this project was going to cost me, I am glad that I waited and I was also very surprised at how many great pieces of wood at an affordable rate I could get.

I wanted to get 3 types of wood and they had to be contrasting species so that they would look great next to one another. So I eventually purchased Brazilian sapele, soft maple and walnut.

I also wanted to sell a few of these after they were made and wanted to supply the glasses that would fit into the flight and not leave that up-to the customer, so I went looking for a case of glasses and man are some glasses very expensive, but I had a specific type of glass in mind and eventually found them at a restaurant wholesale business and they were selling them for $2.00 a piece I thought that was expensive until I started looking some more, I could get another similar glass a little cheaper but the shipping costs were not what I wanted to pay and as well were estimated 10 days out. I needed the glass for its dimensions as that is what I will be building the flight around so I eventually purchased the glasses at $2 each and I had to buy a case, so that is what I did. A picture of the glass is below

Below you can see the woods that I purchased and I always sticker them for at least 24 hours so as that they acclimatize to my workshop.

Here are the boards that I purchased at Barney & Carey lumber, the bottom 2 are maple, the next 2 up are Sapele and the top pieces are walnut.

Here is the close-up of the lumber.

DESIGN

While doing some research I came across so many styles of beer flights, some were nothing more than pieces of pallet wood with a few holes drilled to have glasses just sit on them and some other styles were more elaborate that had a lot more work put into them, I decided to make one that had a lot of character to them, that is why I chose to use multiple contrasting species of wood.

Below are some of the features that the flight will have

Wooden Flight will be made of sapele, walnut and maple woods.

The woods will be cut into strips and arranged in a contrasting way so as to highlight the features of each wooden piece.

It will hold 4 sample glasses.

It will be raised up so as that the glasses will be suspended within the flight.

The top will have a round-over profile that will make it nice to the touch.

The legs will also be made of the same contrasting style of woods so as that it blends with the top.

I think the overall dimensions of the flight will be 13” x 4-1/2” x 2-3/4” high.

I did some preliminary drawings on my 3D software and you can see them below, there might be some subtle changes to the overall design but it should look something like the below pictures.

As you can see from the picture the feet will be housed in a groove beneath the flight itself which will provide a lot of stability for all the beer it will hold. This picture also demonstrates how the glasses will be held.

Here is another 3D image of the flight with the glasses removed, the wood colors are indicative of the actual wood I will be using, these images don’t have a grain pattern to them but trust me after its made it will look awesome.

I will start making this project next week at some point and I will keep you posted as to all progress that I make.

Until then take care.

WHITE OAK LATTICE TRIVETS: FINISHED

I finally finished my last set of trivet’s and there different because of a couple of reasons.

Made from solid white oak

These trivet’s will be sold as a set of 3

There is 2 sizes in the set a big one at 14-1/2” and the smaller trivet is 7” sq.

I did make a set of plans that I will be making available in my shop soon and the plans detail how to make both sizes.

Trivet Dimension Details:

14-1/2” x 7” x 3/4” (Long Trivet)

7”x 7” x 3/4” (Short Trivet)

Tools Needed

Table-saw

1/2” wide dado stack

A power sander , I used a random orbital sander

Finish Used

I used a 1:1 ratio of oil based polyurethane & mineral spirits, I applied 2 coats sanding between each coat with 320 grit sand paper and then finally burnished the trivet with 0000 steel wool.

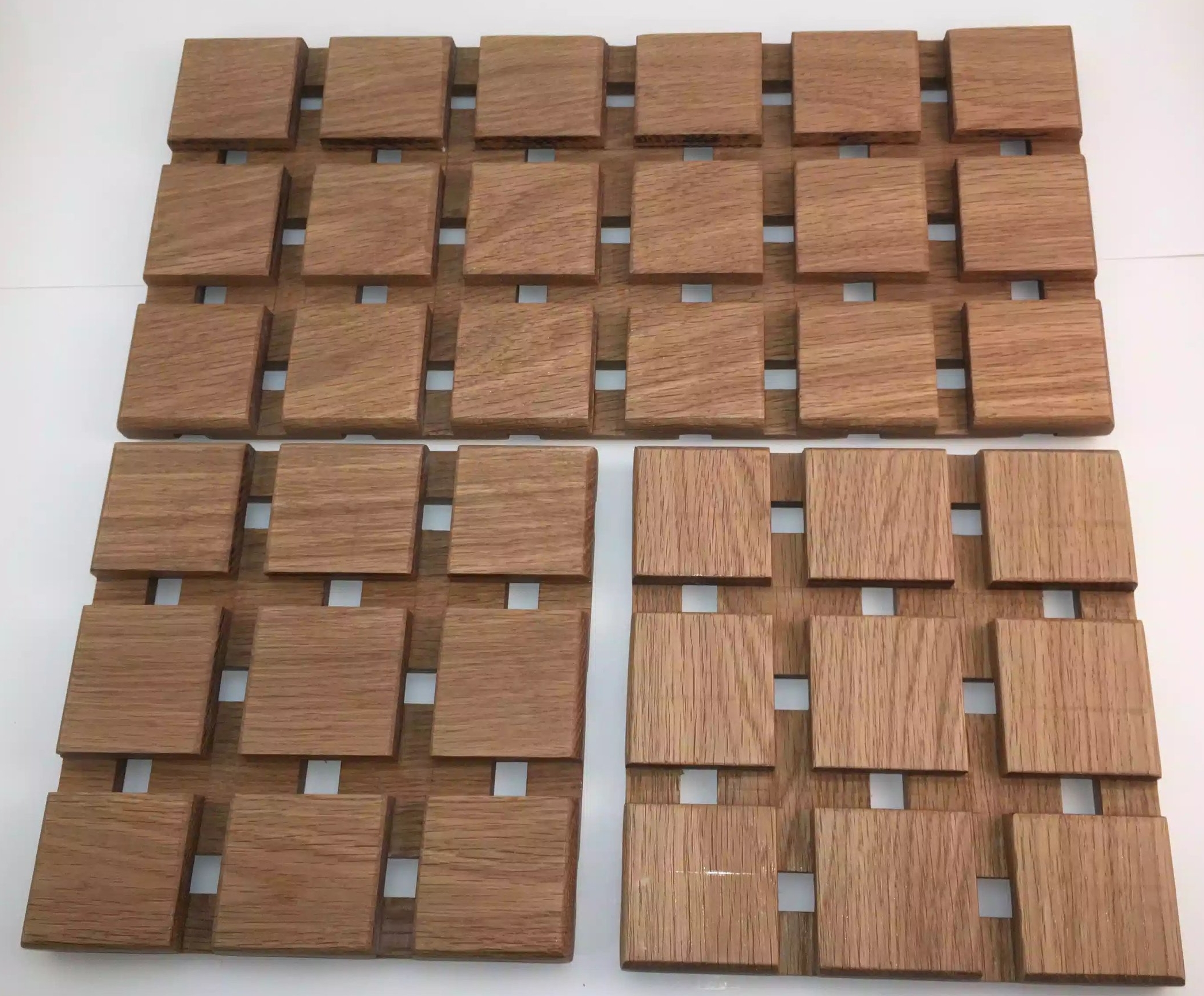

Here is the completed trivet set.

Here is a top view of the larger trivet

Here is a top view of the smaller trivets

Here is a view of the bottom of the trivet set

Here is the bottom view of the larger trivet

Here is a view of the bottom faces of the smaller trivets, I actually like this side of the trivet, but I guess I like the top face more.

I will be making the plans available soon and these trivet set’s will also be available in my Etsy store and my shop here, I hope to have all these items posted in the next few days.

Thanks for reading and see you next.

New Project: More Trivet's !!!!! Going bigger

LARGE TRIVET’S

I have to say that I am definitely love making trivet’s although they may not be a money maker that I hoped for but I will leave them in my shop just in case someone actually comes across them.

Anyway I am moving away from the router made trivet’s just for a change and will be making this trivet on my table-saw equipped with a dado stack. The trivet actually don’t take that long to make but they do take more time sanding and applying finish to them mainly because of the drying time involved. The larger trivet is more than twice the size of the last project I did.

Anyway this is the Process, need to apply finish but that is for another days work.

Purchase the lumber & Sticker it overnight

Ripped the wood to its final width

Crosscut the trivet blanks on my miter saw

Router Table Time

Design & Spacers

Dado stack time small trivet

Larger Trivet

Sanding & More Sanding

PURCHASE THE LUMBER & STICKER OVERNIGHT

I purchased the lumber at the same place I bought the red birch for the last trivet’s I made from at Barney & Carey Lumber located in Avon, MA. but this time I purchased white oak for my current project, I have used red oak in the past but I purchased it big box stores and let me tell you the quality difference between the two is huge.

For the lumber to dry properly, you’ll need to sticker your pile. Stickering refers to the use of narrow strips of wood – typically 1”x 1” – between the layers of lumber to allow adequate air flow. For best results, the stickers should all be the same length (the same as the width of the pile) and rot- and stainfree (to minimize staining your lumber). In a perfect world, the stickers would be dry, but billions of feet of wood have been stacked using green stickers created in the board edging process with perfectly adequate results.

I sticker-ed the wood here using some scrap wood to separate the two boards.

RIPPED THE WOOD

So my first step was to rip the wood to its final width and I figured it better to do this before I cross-cut the wood into their respective trivet sizes, anyway its better to rip one board than 20 of varying sizes as you are removing or lowering the percentages of error.

I used my feather-board to make sure that the board didn’t move away from the rip fence, I also used a rip blade for this process.

CROSS-CUTTING TIME

Next step was to cut the trivet blanks and I used a set-up on my miter saw station where I used a stop block but because I was making two sized trivet’s I made 2 sized spacers, so placing the the stop block I measured the distance for the larger trivet and cut a spacer to that size, then measured the distance for the small trivet and created another spacer block to that dimension, below you can see some pictures of the process, this makes it very easy to repeat cuts and makes the operation go a lot smoother and removes the need to measure every single trivet that needs to be cut.

Here you can see the oak sitting on the miter saw deck and the spacer block is establishing the positive that I need to make all cuts the same size.

Here is a image of the stop block and its nothing more than a scrap piece of ply that I cut to make sure that all the large trivets are the same size, I also made another one for the smaller trivet. Not the metallic production stop this never moves and I can swap out the 2 spacer blocks dependent on what size trivet I am cutting. It worked like a charm.I also label each spacer block so I wouldn’’t get then confused.

ROUTER TABLE TIME

The next phase of the build was to add a round-over to the trivet on all faces I figured this would be a lot easier to do while the the trivets were still blanks and did not have a ton of grooves and dadoes for the router bit to get stalled on. So using my router table with a 1/4” round-over bit in the router I made a couple of passes to remove all the sharp corners.

Here is the router table with the but installed.

Here is a close-up of the round-over bit.

All 3 trivet blanks have the round-over now and really feel smooth to the touch.

Here is a close-up shot of the round-over, looks and more importantly feels great.

I meant to say that before I brought the pieces to the router table I wanted to make sure that I put the trivets in sequence as to how they were cut from the board that way I was maintaining the boards natural grain direction and making it look really nice. Below you can see what I mean, I also marked the best face for the top of the trivet.

Here is the boards with the grain direction flowing right through the board, I also marked this face as the top of the trivet.

DESIGN & SPACERS

I came up with the design on my 3D software Sketchup and I actually made it in the last batch of trivet’s I made and thought that this design would look really nice if it was a lot bigger, I made a quick and dirty set of plans to follow so as that I put the grooves in the right places.

To help me all the grooves and dadoes that made up the design of the trivet I needed to make some spacer strips so as that I could repeat easily on every trivet.

Here are the spacer strips that I would use to align the table-saws rip fence to the trivet, I also marked each spacer width on the board so as that I didn’t use the wrong one.I used 6 spacers in total with measurements of 3/4”, 2”, 3 1/4”,4-1/2”, 5-3/4'“ and 7”.

DADO STACK TIME

To make the trivets I decided that I would use my dado stack. The trivet is not that hard to make but it does require a decent amount of concentration as it is easily screwed up. The lattice design is eventually created by rotating the board and using the spacers in designated areas. I was working both faces of the trivet. I will try my best to give accurate step by step below.

STEP 1: SMALL TRIVET

Place a 1/2” wide dado stack into the table-saw and raise it 3/8”. Since I am working on the small trivet I start with the 2” spacer strip as seen below. Run the the trivet blank through the Dado Stack which I will be calling DS from now on.

Here is the 2’ wide spacer strip to position the fence 2” away from the cutting edge of the DS.

STEP 2:

Here you can see the trivet positioned to cut the 1/2” wide 3/8” deep groove, once one side is rotate the trivet 180° to catch the other side. Now you will need to rotate the trivet so as that you can position 2 more grooves running perpendicular to the grooves you already made

Here you can see the trivet positioned to cut the 1/2” wide 3/8” deep groove, once one side is rotate the trivet 180° to catch the other side.

Now you will need to rotate the trivet so as that you can position 2 more grooves running perpendicular to the grooves you already made. After this is done you trivet should look like the picture below

After step 2 your trivet will look like this, you will have 9 squares measuring 2”x2” and they are all on the same face (this is the top)

Step 3

Next we move onto cutting the grooves on the bottom face of the trivet, this is what determines the lattice style, if you dont like my spacing you can always use your own imagination to come up with your own design, anyway

With the 1/2” dado stack raised 3/8” high we are basically going to run grooves on the bottom side splitting the squares on the top in half but from underneath the top face, confusing I know but the pictures will help.

So using the 3/4” spacer to determine the distance from the blade to the rip fence we will run the trivet through the blade, after you run the trivet through the first side rotate the work-piece 90° and do the other 3 sides

Here is the orientation of the trivet being run through the blade, the groove will be 3/4” from either edge and what this does is places a groove directly under the 2” x 2” squares on the top

This is what the trivet should look like now, all the outside edges should have a slot cut in them.

STEP 4

This is the final step in cutting the grooves on the small sized trivet.

Using the 3-1/4” sized spacer to set the distance from the fence to the blade, this will center the dado stack in the middle of the work-piece to place one more groove.

Here is the 3-1/4”spacer

Here is the finished trivet, still need to sand it as there was a lot of tear out

Other than sanding the trivet down the smaller of the 2 trivets are made, I need to do a lot of sanding as you can see there is a lot of tear out, I need to figure out a way to reduce the amount of tear out as this will take a lot of sanding to make nice to the touch.

NEXT : THE LARGER TRIVET

The larger trivet is 14-1/2” long x 7” wide and is also made using the same lattice pattern as the smaller trivet, my goal is to sell these as a set of 3.

STEP 1

Using the 2” wide spacer block to determine the distance of the blade from the fence I ran the board through the blade along its length to establish the 2” wide squares on the top face then a swung the board to its other side and repeated the cut, creating 2 grooves running the length of the board .

Here is a picture of the 2’ wide spacer to determine the distance from the blade to the rip fence, after the rip fence is clamped I remove the spacer block and run the board through.

I forgot to take a picture of the work-piece with just the 2 long slots cut, just disregard the under side cuts, that will be covered later.

STEP 2

So using most of the spacer blocks I start cutting all the cross grooves on the bottom of the trivet creating the lattice effect for the trivet.

I started with the 3/4” spacer and got all for sides of the bottom of trivet, then moved onto the next spacer which is 3-1/4” wide and again completed 2 across the grain cuts at each of the ends, next spacer was 5-3/4” and again I cut 2 across the grain grooves on each end and finally I used the 7” spacer and this located the center of the trivet and you should have a trivet that looks like this below.

Your trivet should look like this all the grooves in this past step were on the bottom face of the work-piece.

Here is the completed bottom face of the trivet, I did however make an error I used the 7” spacer on the bottom and I didn’t need to that spacer was only to be used on the top but it turned out OK and I left it, that is why the middle of the top face of the trivet has that longer rectangle instead of 2 squares

THE NEXT STEP

Now that all the grooves were cut on the bottom of the trivet I needed to make the grooves that set up the 2” squares. As I mentioned above I made an error when I was doing the final cut on the bottom of the trivet I used he 7” spacer and I should not have because that spacer was for the top side, so as it turned out that I have bigger squares in the middle of the trivet and not 2 the same size as the rest. I determined that it actually didn’t look that bad and left it as a design element.

So lets move on

I started milling the top of the trivet and I started with the 2” wide spacer and cut the grooves on each end of the board, then move onto the 4-1/2” spacer and cut 2 grooves on each end of the board and that is it. If i had followed my plans I would have used the 7” spacer next but since I already used that on the bottom I could not use it on the top as it would have divided the trivet into two halves and I didn’t want that .

In this picture you can see the grooves left by using the 2’’ wide spacer when you turn it end fro end you get both grooves without re-measuring and that is said for all spacers except for the 7” spacer which was used to locate the middle groove of the work-piece.

Here is the plan of what the trivet should have looked like but instead we have whats below, I don’t think it looks bad at all, sometimes mistakes look good.

Here is the finished large trivet.

SANDING

So after all the table-saw work was finished I needed to do a lot of clean up work on the trivet’s as there was so much tear out , if your not familiar about tear out this happens when you are cutting wood with machines or by hand and what happens is that unsupported wood fibers blow out, I found an interesting article in Popular Woodworking that describes tear-out.

I need to do some more research and try and come up with a solution that will prevent large-scale tear out. Below are some pictures of the tear out that I had on my trivet’s.

Here is all the tear out I had on the underside of the trivet. All of the broken wood fibers is what tear-out looks like.

Here is a closer look at the tear out on the bottom face.

Here is the tear out I had on the top of the trivet

SANDING & AIDS

This tear out will be easily removed in some locations and other areas will require a little more work. I found the tear out really bad on the underside of the trivet especially in slots that were cut, so to remedy the problem of sanding in tight quarters I made some home made sanding blocks, these are nothing more than scrap wood, but the wood had to less than 1/2” thick as that is the width of the grooves we cut, then I used various grits of sanding paper to smooth out the edges.

The top and bottom faces of the trivets were easily sanded as they were flat and I didn’t have to contend with the grooves, I used my orbital sander moving from 120 grit all the way up-to 400 grit and its very smooth now.

Here are my aids, 3/8” thick scrap piece of wood that I used to wrap the sandpaper onto and moves in and around all the grooves with ease.

Here is what the trivet looks like now after a decent amount of time spend sanding them, is it done ?? I ask myself and I say no because all the over lapping milling marks left behind by the dado blade are not totally gone so I will need to return and do more, but as you can see the difference in the before and after is a big difference.

Before sanding

Before Sanding

After sanding, this is the bottom side of the large trivet

After sanding on the top face of the trivet.

So after all the sanding done today there is a huge difference but before I go into production mode I need to figure out some solutions to some of the problems I encountered making this set.

Need to solve the tear out :- I might try cutting reducing the depth of cut and not taking out all 3/8” at one time, also considering alternating the with the grain and against the grain cutting, if I do all the against the grain cutting first hopefully cutting with the grain will also reduce the tear out.

Making sure I font repeat the mistake that resulted in a groove being placed in the wrong place, this cut have been a costly mistake but I was lucky that it didn’t ruin the trivet, this one is easy slow down and follow the plans .

Below are the 3 trivets that I made using this design and I have to say that they look great and especially like the white oak that I used but to be honest I like the red birch better, but the red birch had a lot of wood burn where as I didn’t get that with the oak.

Here is the finished set, there is almost 30” of space to hold hot plates and casserole dished or even a Thanksgiving turkey

You can arrange them any number of ways this is just another example.

NEXT:-

I need to apply the finish to them but to be honest this is a rinse and repeat from the last batch of trivets that I made using 3 coats of 1:1 ratio of oil based polyurethane and mineral spirits and after that has dried I will burnish them with very fine steel wool.

Trivet's Now On Sale!!!!!! But Limited Stock

Hello everyone,

I know that its been little while but better late than never, I am excited to announce that for the first time since I launched this site I am able to bring you my very first physical product line that everyone can use at home, as a gift, or just as a decorative table ornament that can be used with all the special holidays that are coming up.

I also want to inform that I am still keeping the site with Squarespace but I have partnered with Shopify to facilitate all my fulfillment services, so don't worry when you purchase a physical item on my site and are transferred to another site for Checkout. Right now all my digital plans will still be handled right here.