MEASURE TWICE, CUT ONCE

Most woodworkers don’t give much thought to most basic tools in their shop, they

are too busy picking out the best chisels, scrapers, clamps, special jigs, tool,

woodworking machinery, hand planes and all manner of accessories to make

their work go smoothly and more accurate. What they are missing is the

measuring and marking tools.

Look at what you own in the way of measuring and marking tools. Many of the

frequent troubles in woodworking are out of a four-sided figure frames, casework,

joints that fit poorly, etc. can be traced back to the measuring and marking

mistakes. The culprit is usually only a matter of using the incorrect measuring

and marking too for the job. A tape measure was not calculated for the extremely

accurate measurements that most woodworking projects require.

Making for some exacting work, in most woodworking projects, the first thing you

do is marking and measuring linear dimensions. Miscalculations as small as

100th of an inch when marking and measuring in such complicated joinery or

small, tight parts will later show up as gaps in joints or uneven parts or a host of

other less-than-perfect results.

Depending on how correctly you are able to interpret a measurement into an

objective mark on a piece of wood is the outcome of measuring from point 1 to

point 2. Holding down a tape measure while trying to accurately mark off a

measurement is a difficult task, mainly because tape measures are not meant to

lay flat. An accurately calibrated and readable marking and measuring tool is

needed for all woodworking projects.

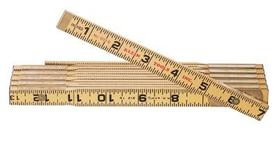

RULES & TAPE MEASURES

Since even the best measuring tools are relatively inexpensive, most

woodworkers acquire a variety of rules and tape measure to meet different need.

However, it is advisable to use the same rule or measuring tool throughout the

project, just in case there is any variation between one tool and another.

Purchase both rules and tape measures with standard and metric graduations –

but take care not to confuse one system with the other once you have begun to

mark out a work piece. You can measure one piece of wood accurately and then

use it as a template for the other pieces if more than one of the same size is

needed, this will save you time in the marking and measuring department.

SQUARES & T-BEVELS

Squares are used to make sure things are at a right angle to one

another. In a woodshop, these things might be the edge of a board, the shoulder of a

tenon, the fence on a jointer and so on. However, square is an abstract term.

Looked at closely enough, nothing is truly square; some things just approach the

idea of being square than others. There are four types of square generally

used in woodworking.

MARKING TOOLS

Your shop may be filled with the finest cutting and shaping tools money can buy, but if you don't measure and mark precisely, your project parts will fit like a cheap suit. Perhaps that's why woodworking catalogs offer page after page of products promising to make you a more accurate woodworker. To help you sort it all out, here are the marking tools we find very useful