About 5 years ago I decided to build out my own woodworking shop in the basement, my father in law had a paint workshop and when he passed away I decided to use the space for a woodworking shop.

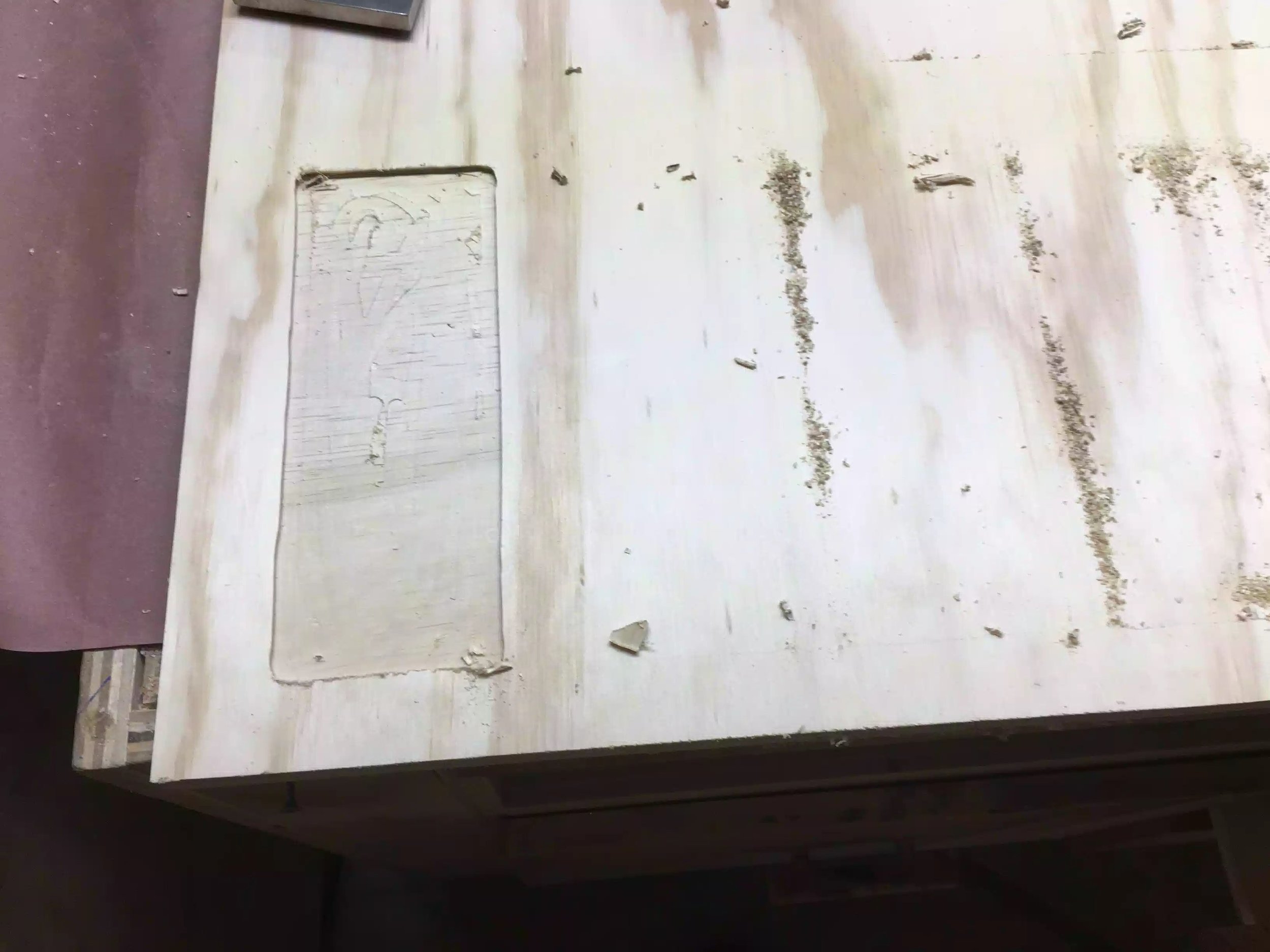

There were a decent amount of tools in the shop for painting but he had a few woodworking hand tools that looked in bad shape most of them were hand planes and old ones at that, I always said that I must restore them as I thought they would come out good looking and would actually be very function-able hand planes, but alas I never did until last week when I looked around my shop and realized at how many power tools that I had but had very few hand tools, sure I had a few chisels and marking tools, but I didn’t have any planes or various saws so I decided that in the coming months since I don’t have any major projects that I would start building out my hand tools and eventually make a nice hand tool cabinet.

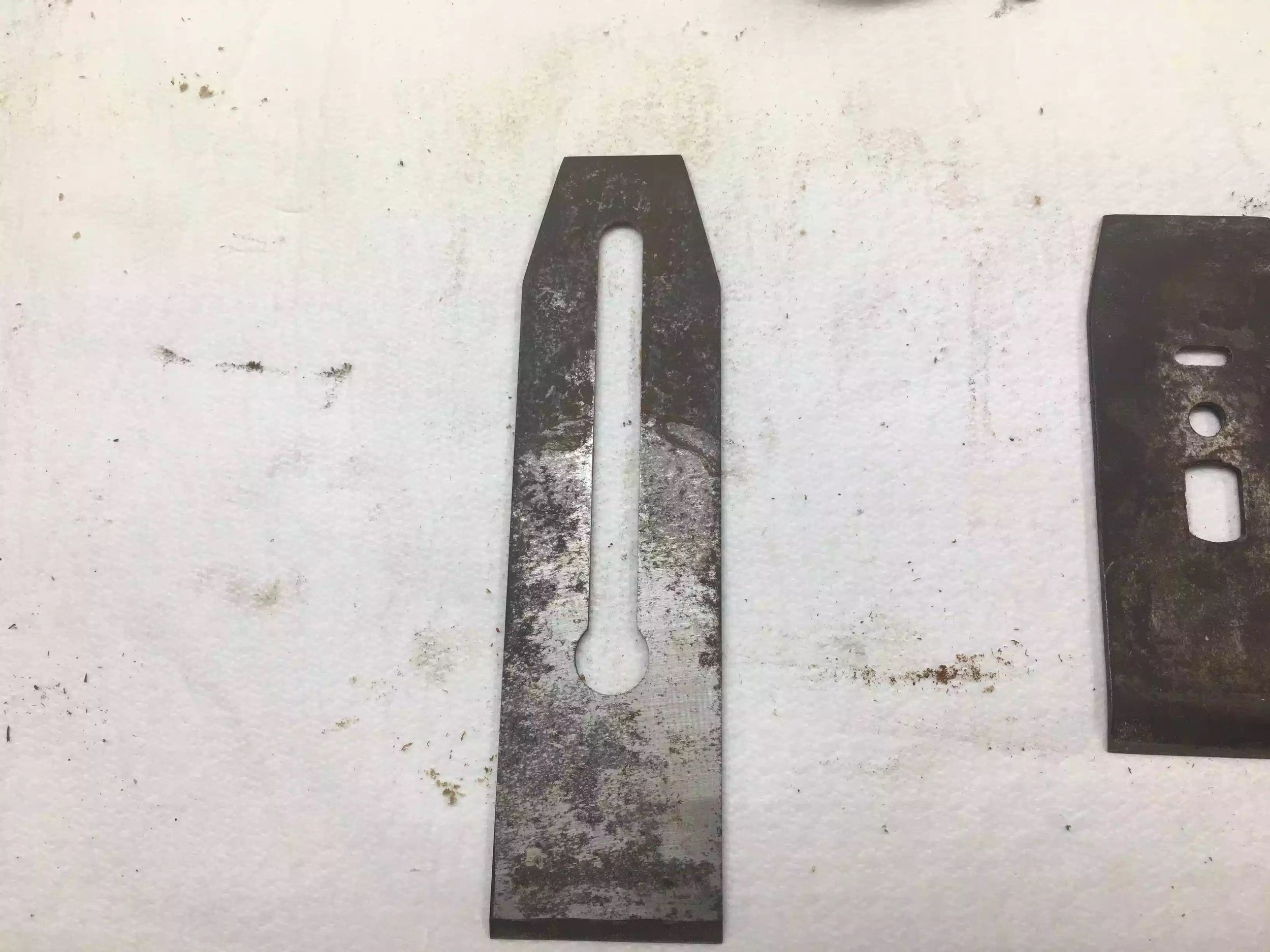

THE HAND PLANES

My father in law had 3 hand planes that I am looking into restoring and I believe they are

My first order of business was to do research on how to actually restore a plane as I never did it before, so I read woodworking articles, borrowed library books and watched countless You Tube videos before I undertook this process.

There are so many resources available on the internet on how to do this but I used various tips from different people on the Internet to aid me in this project. Below are some links and YouTube videos that I though would help.