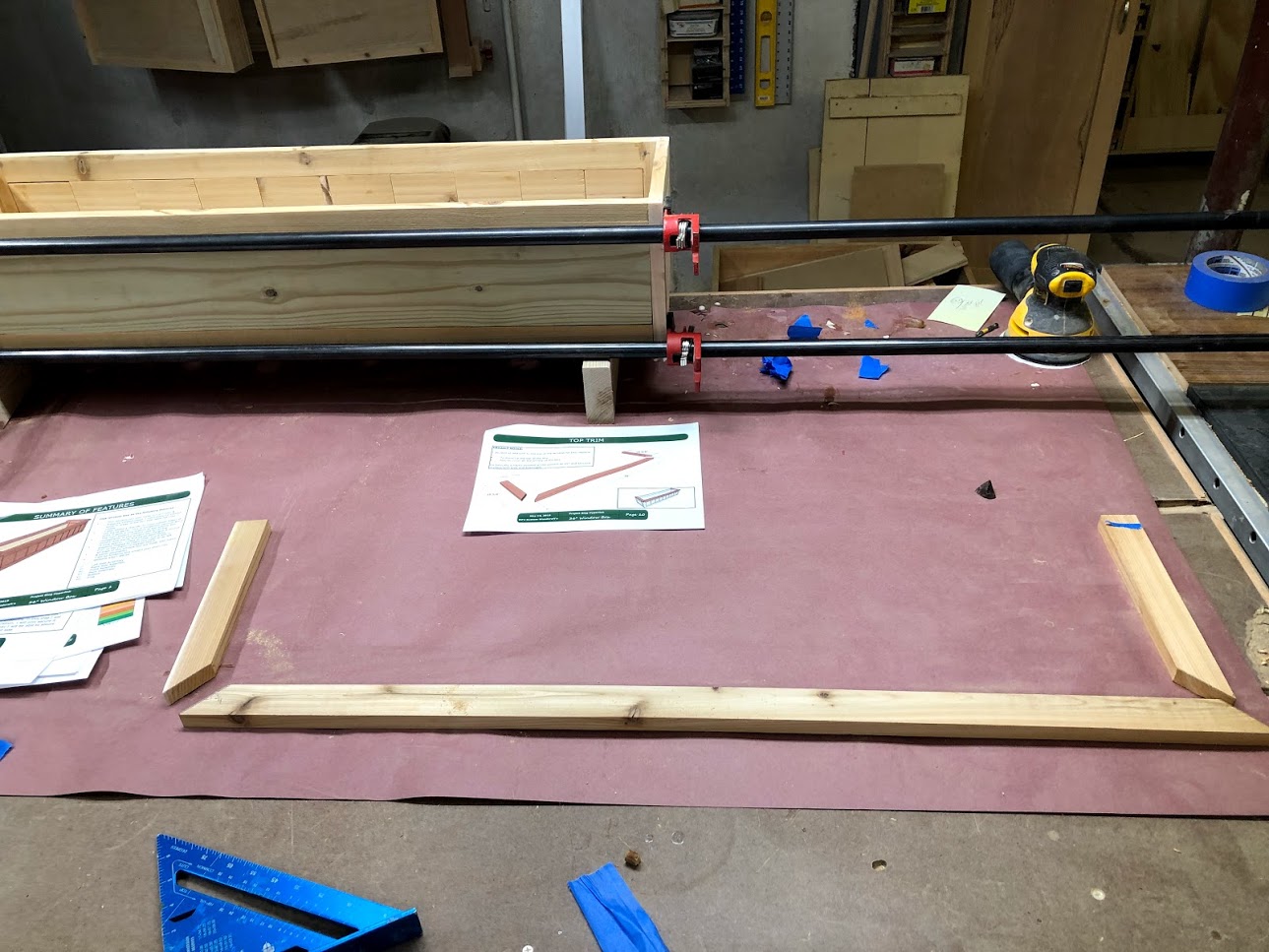

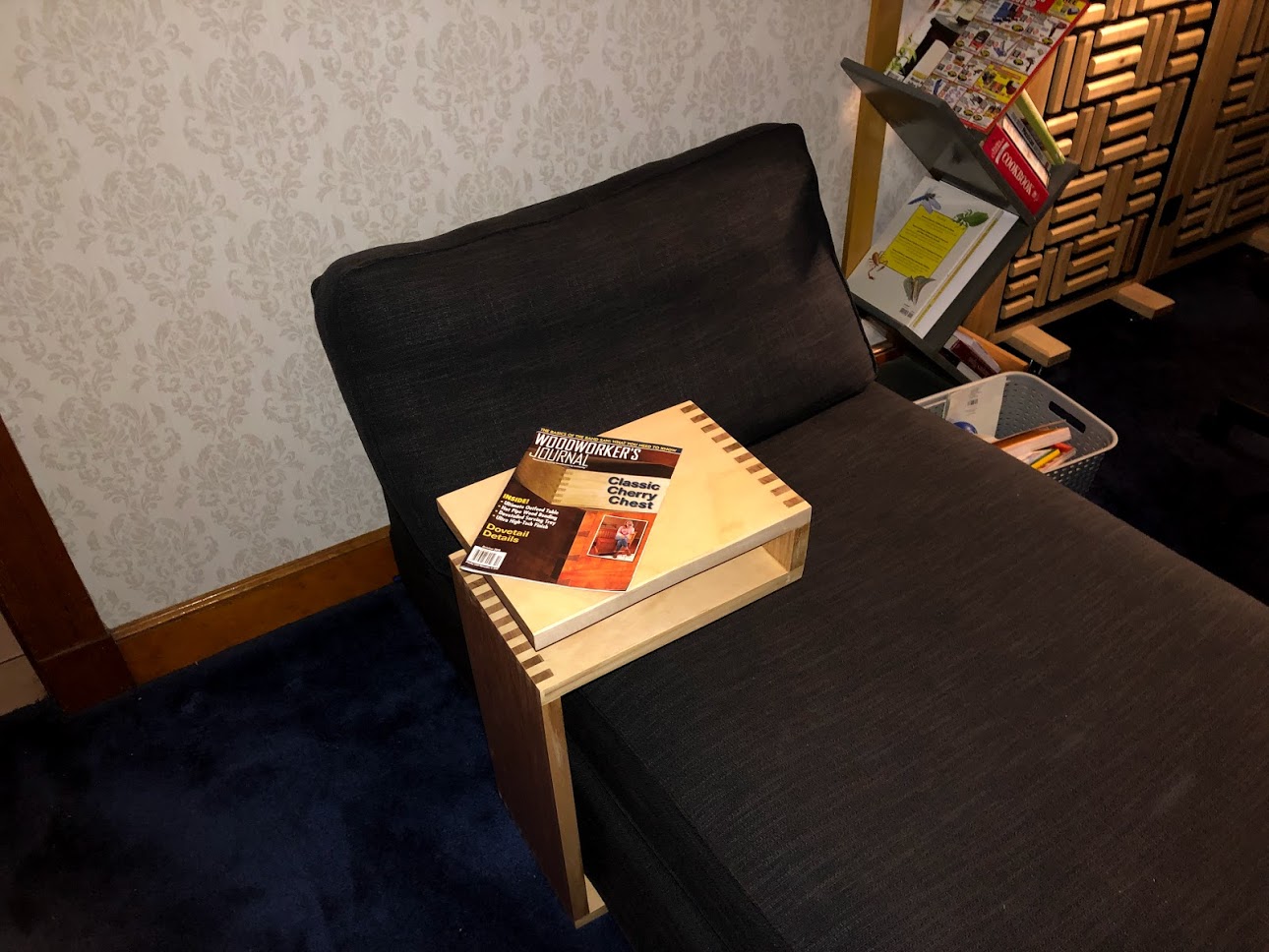

Well this weekend finally saw me complete all 3 window boxes. I made 2 different sizes and used 2 different wood types let me go into a little more detail about them.

CEDAR WINDOW BOX

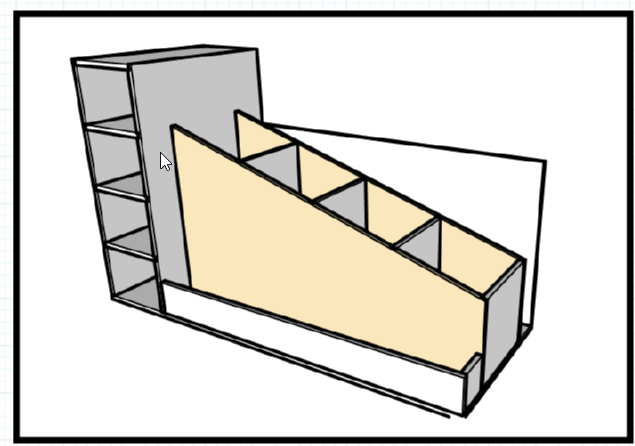

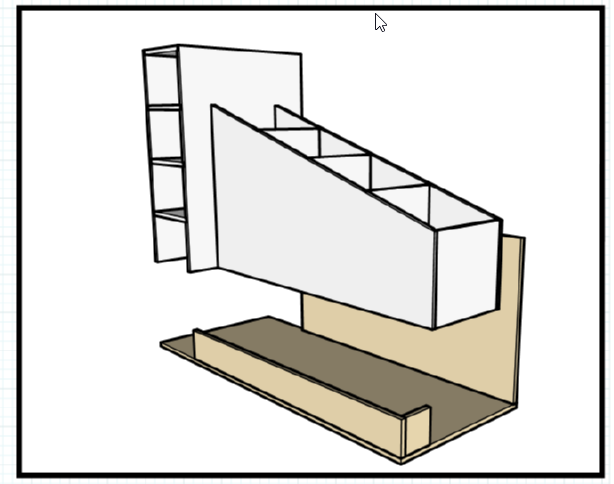

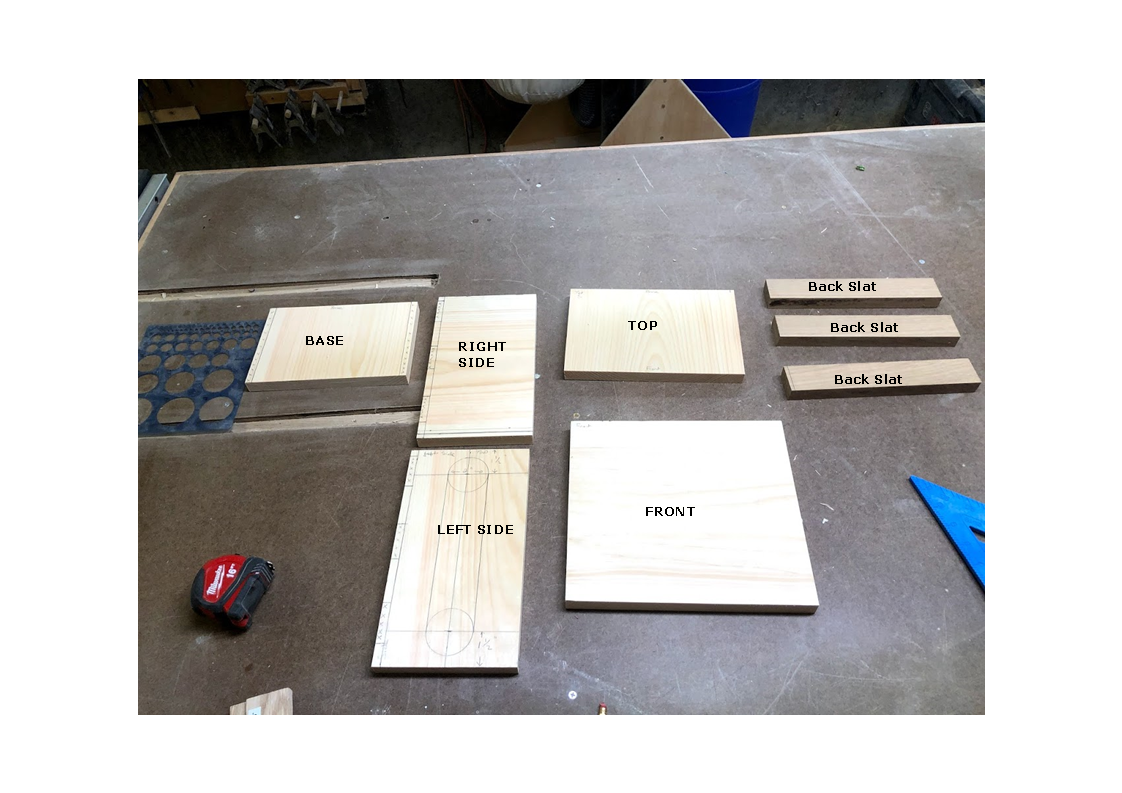

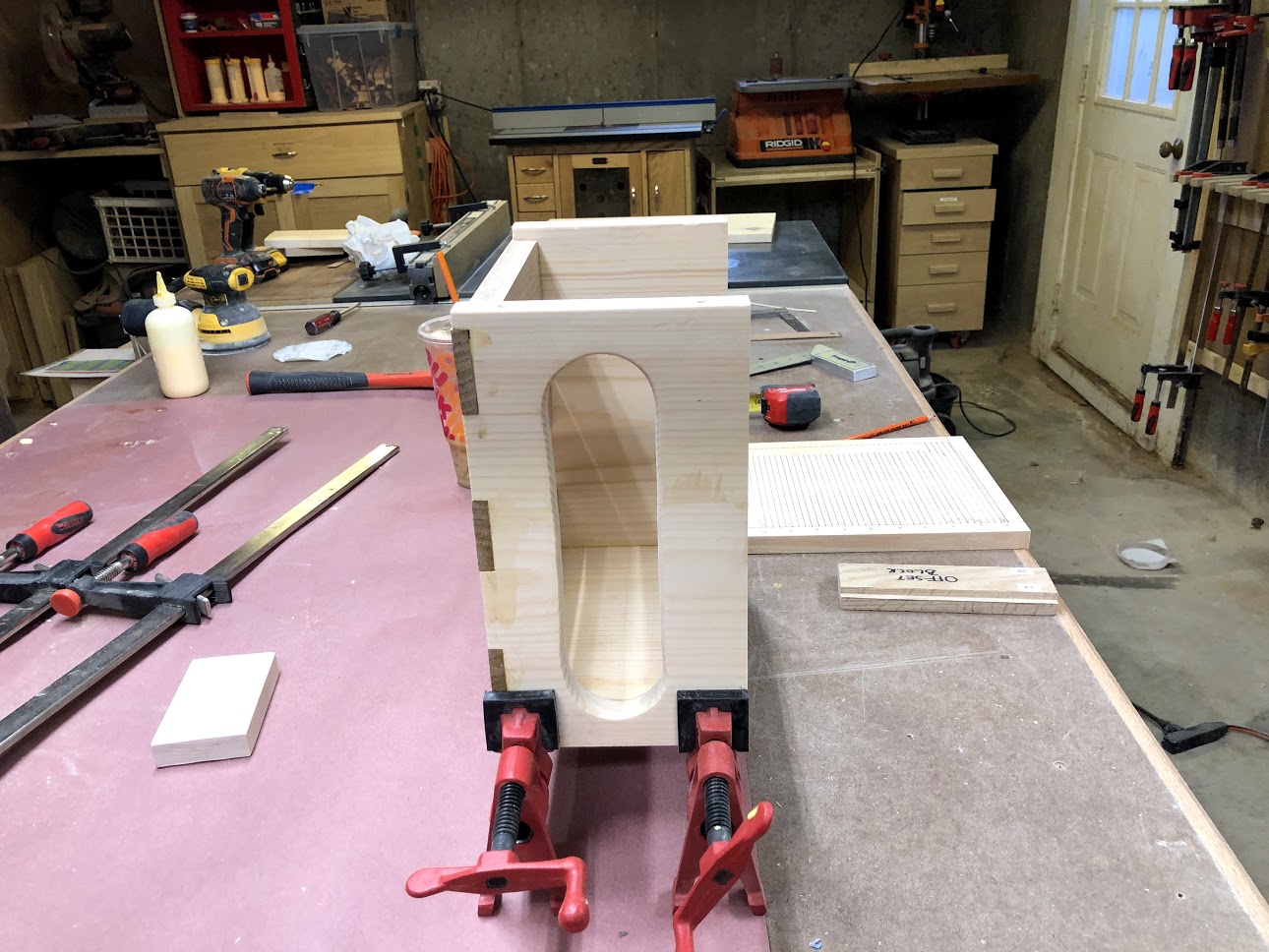

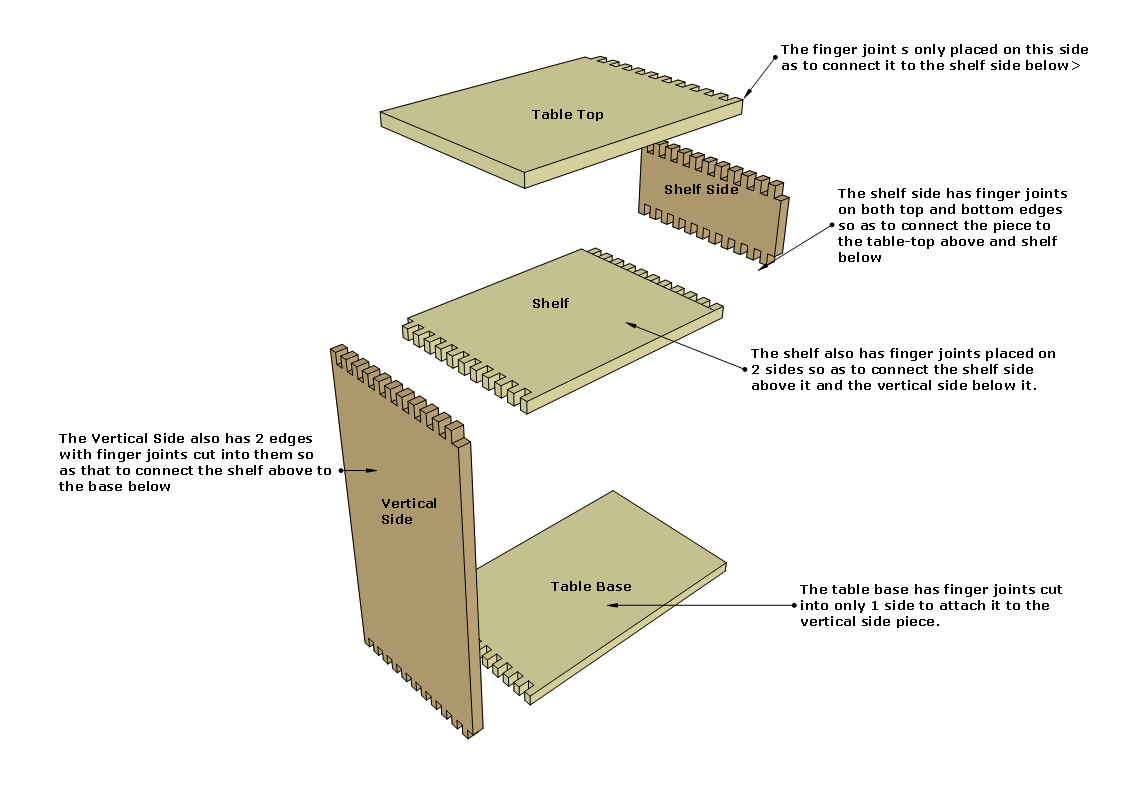

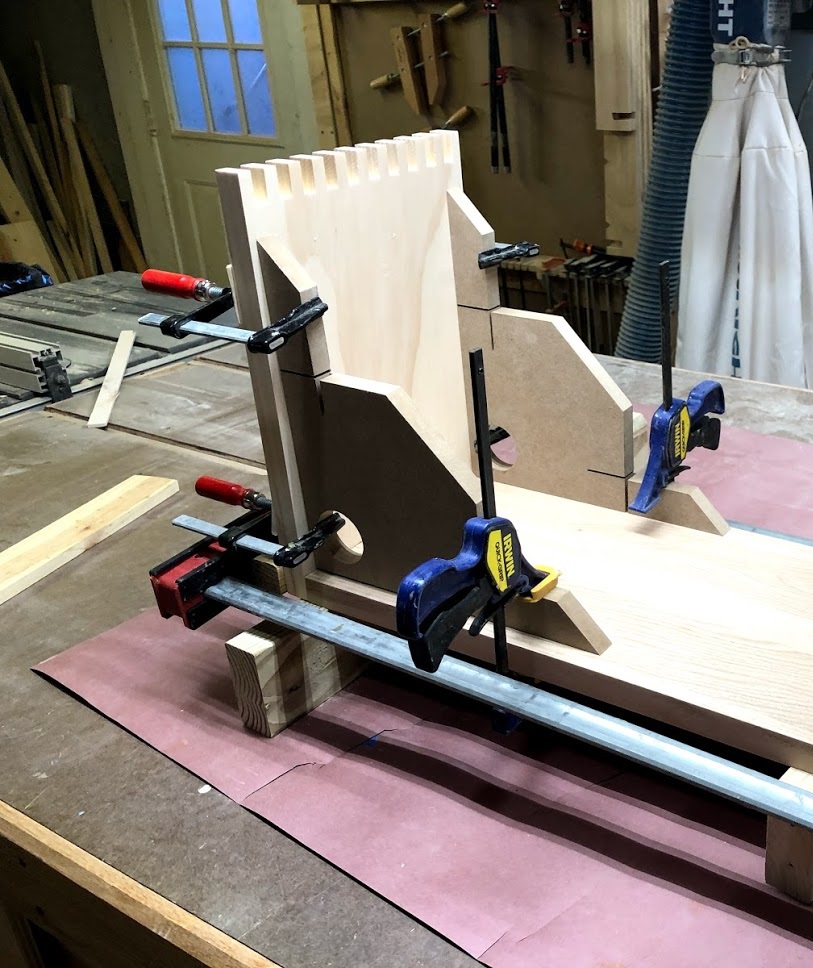

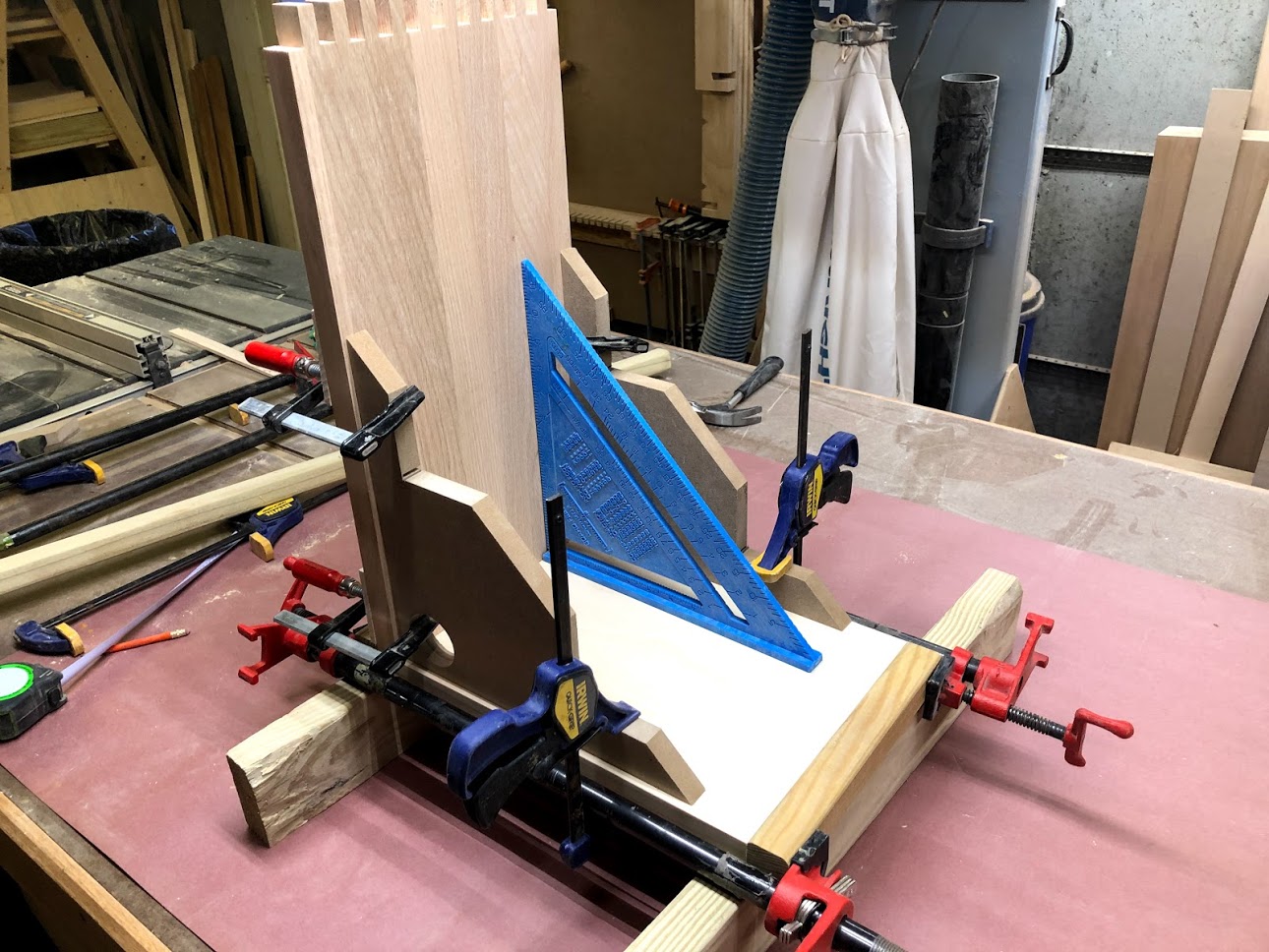

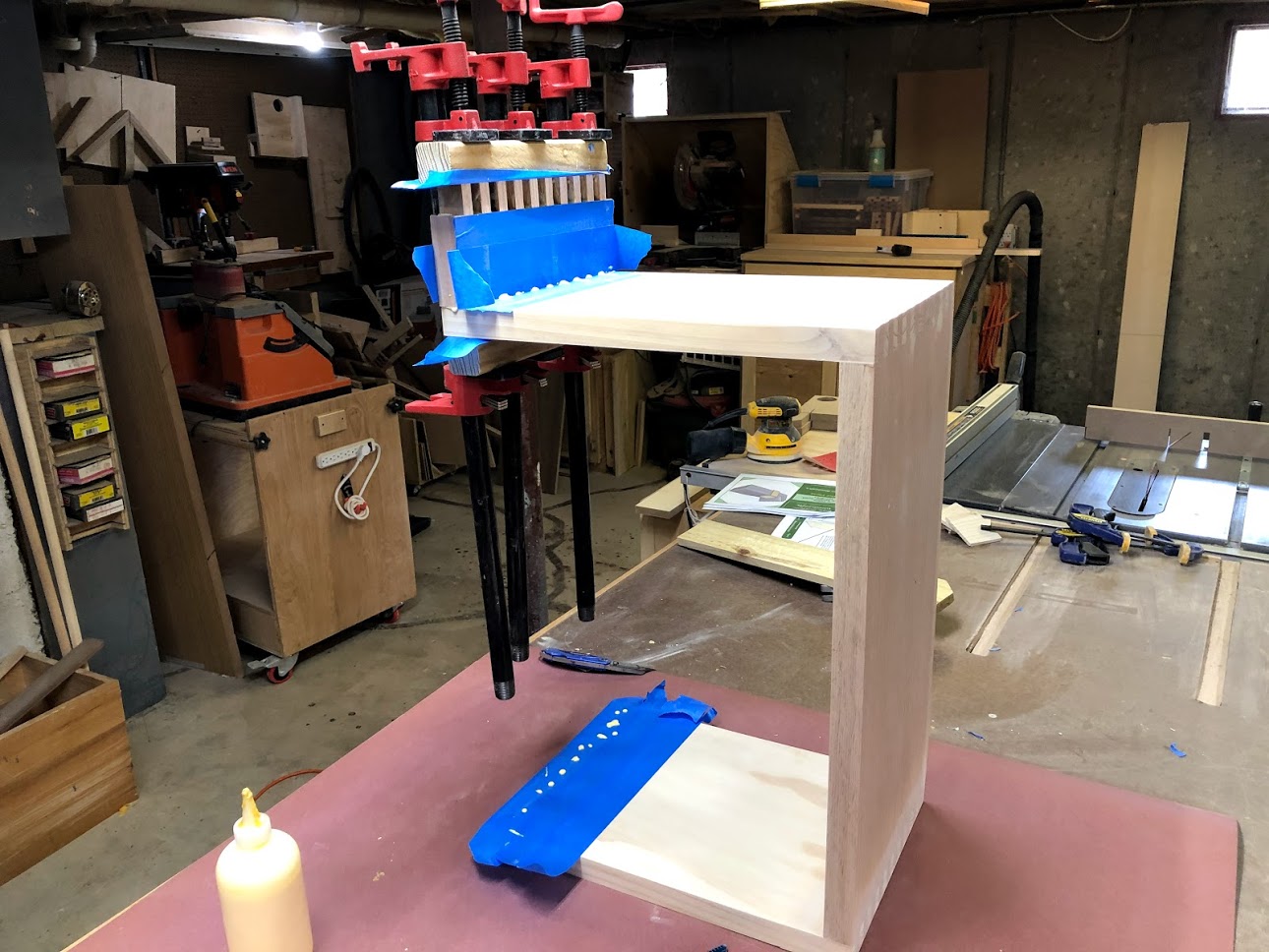

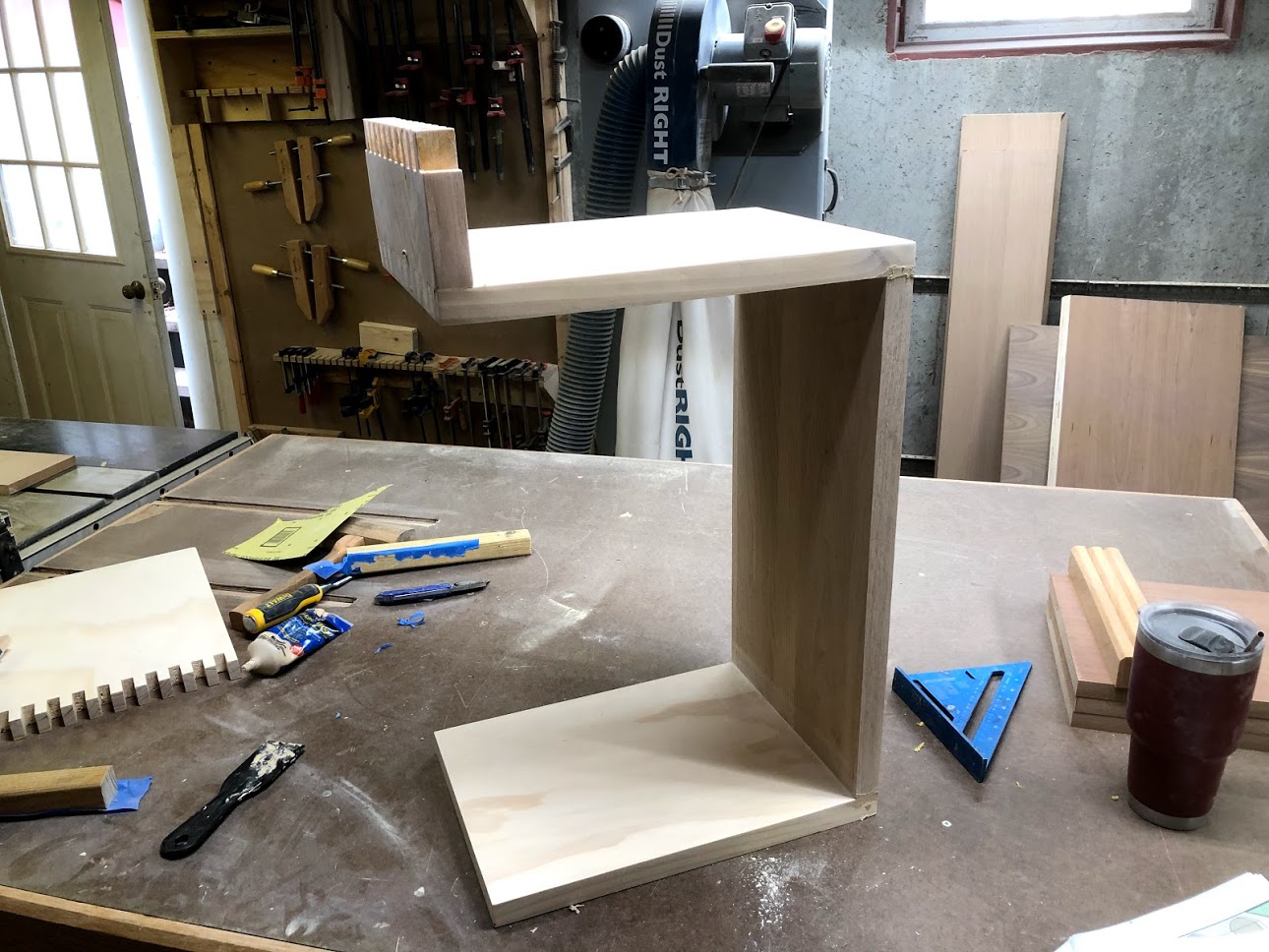

The first window box that I made I used cedar wood to make it, I used frame and panel construction techniques to make it. It is also the largest of the 2 sizes of box that I made at 40'‘ basically because I had to purchase a long cedar board so I decided to use the entire board and have no scrap left over.

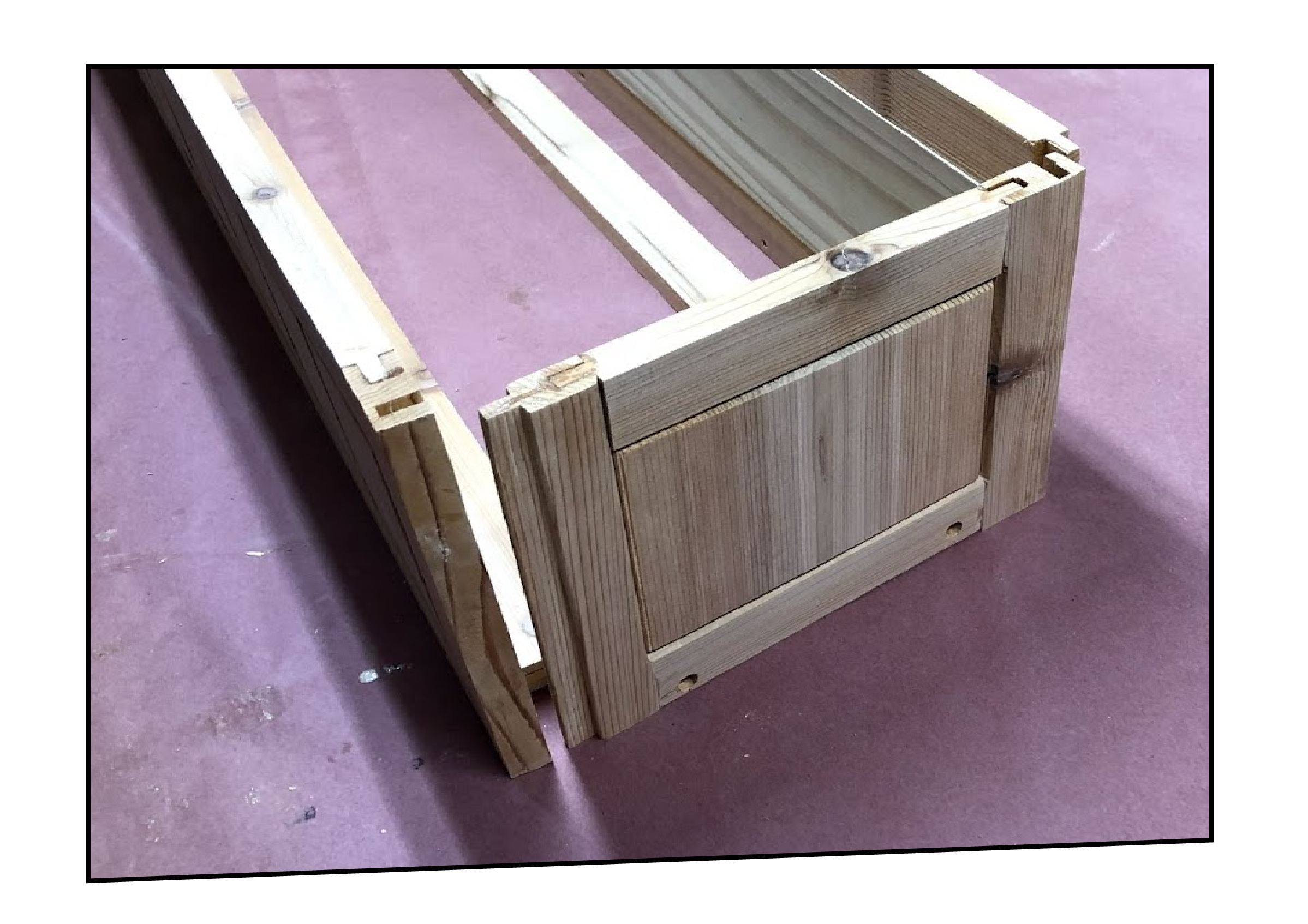

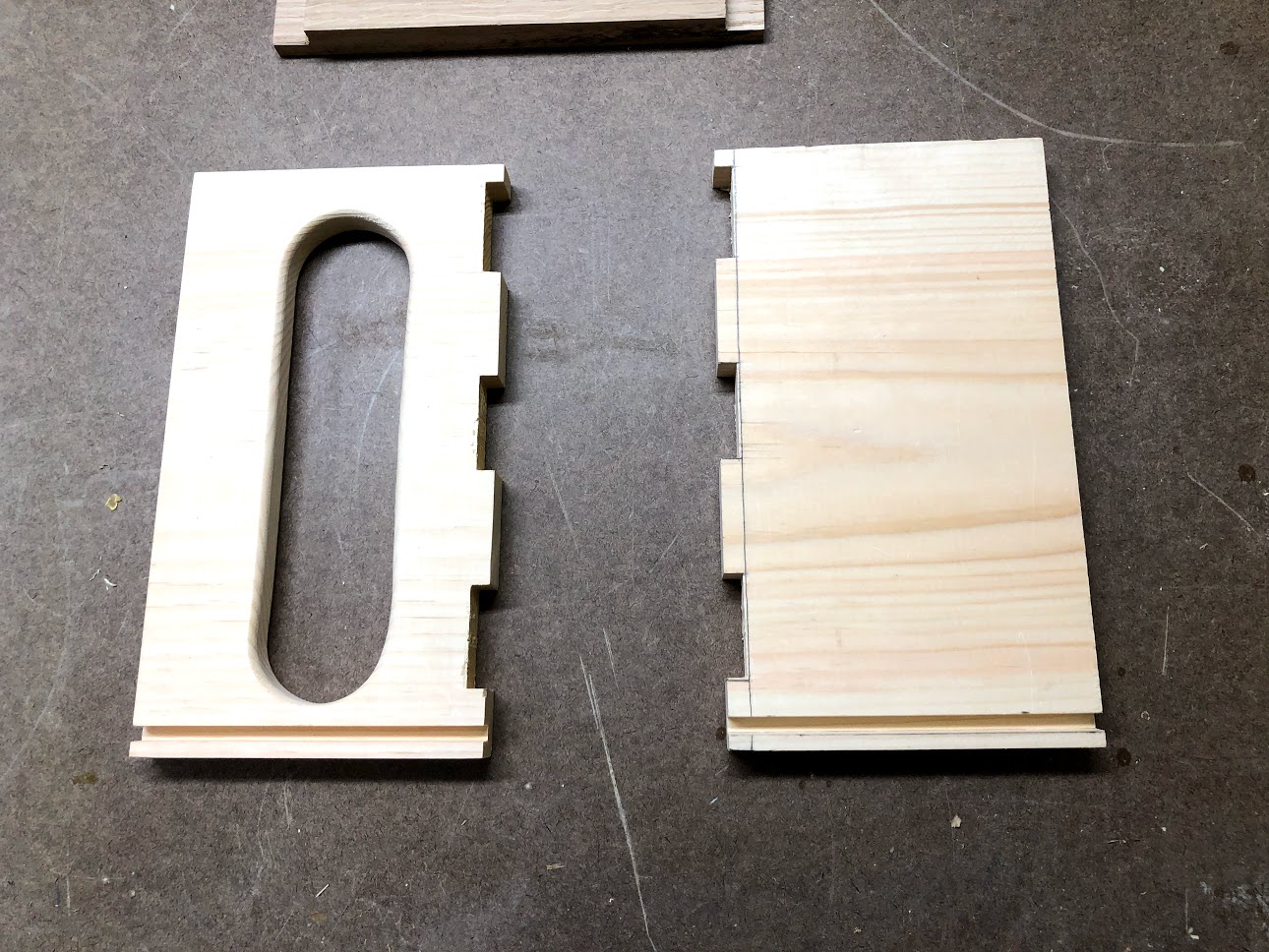

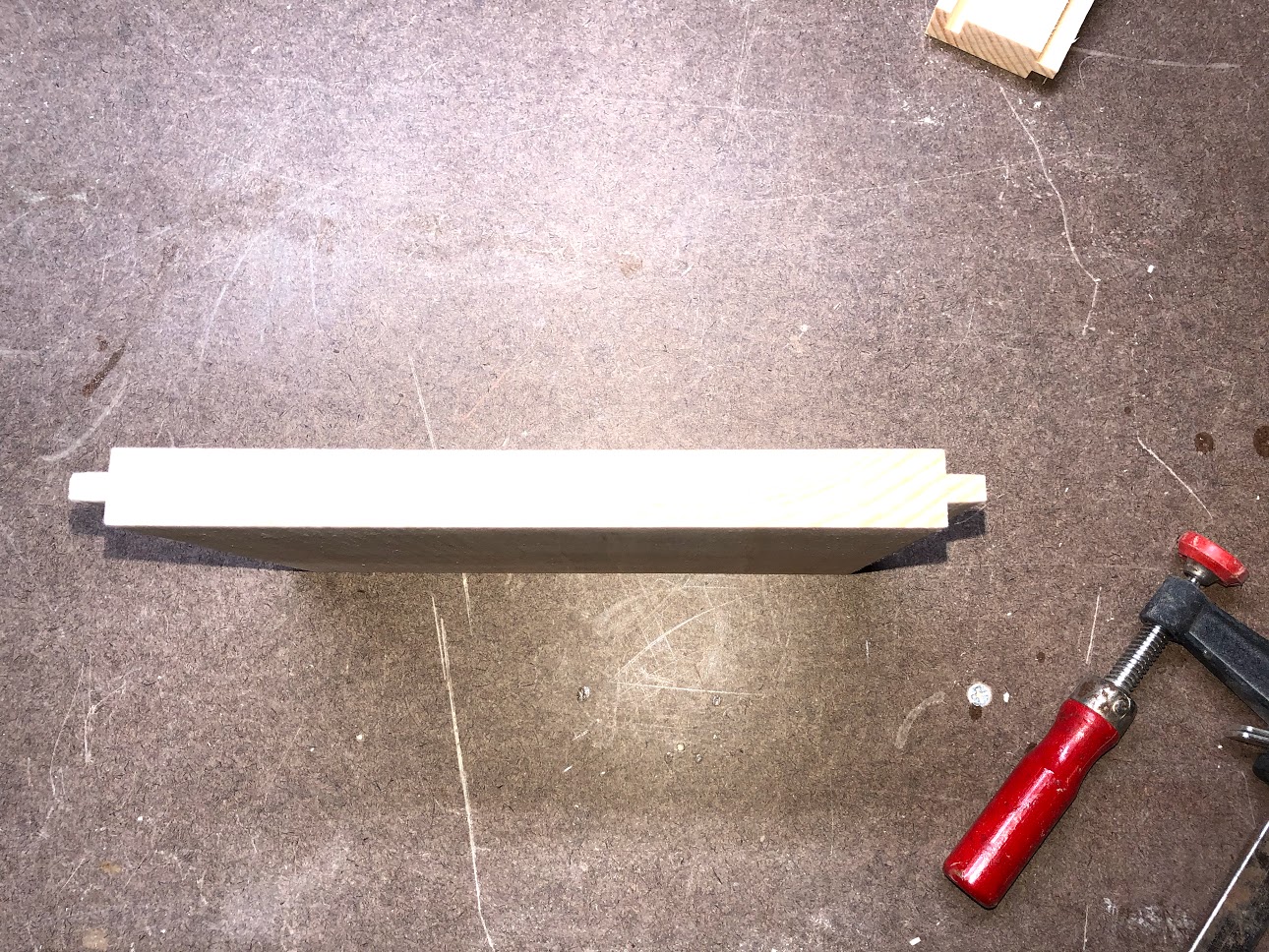

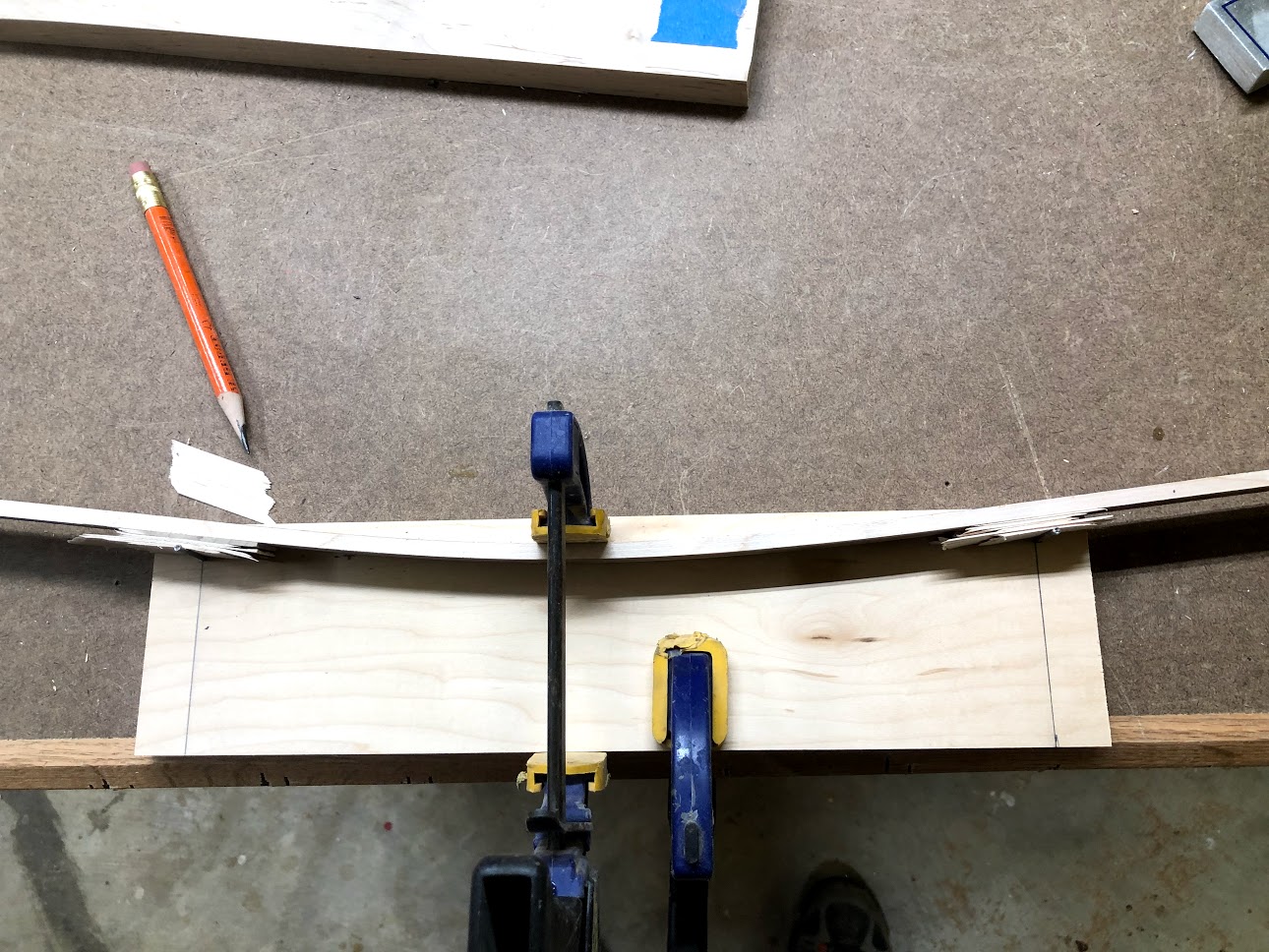

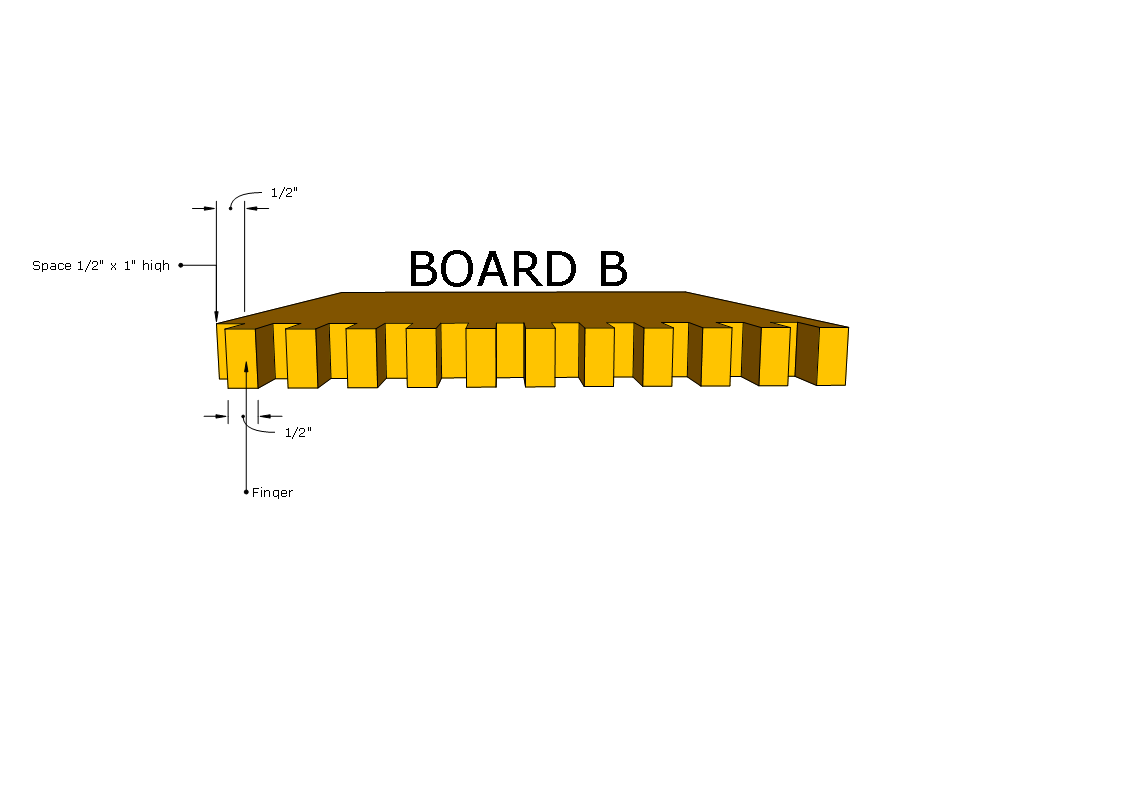

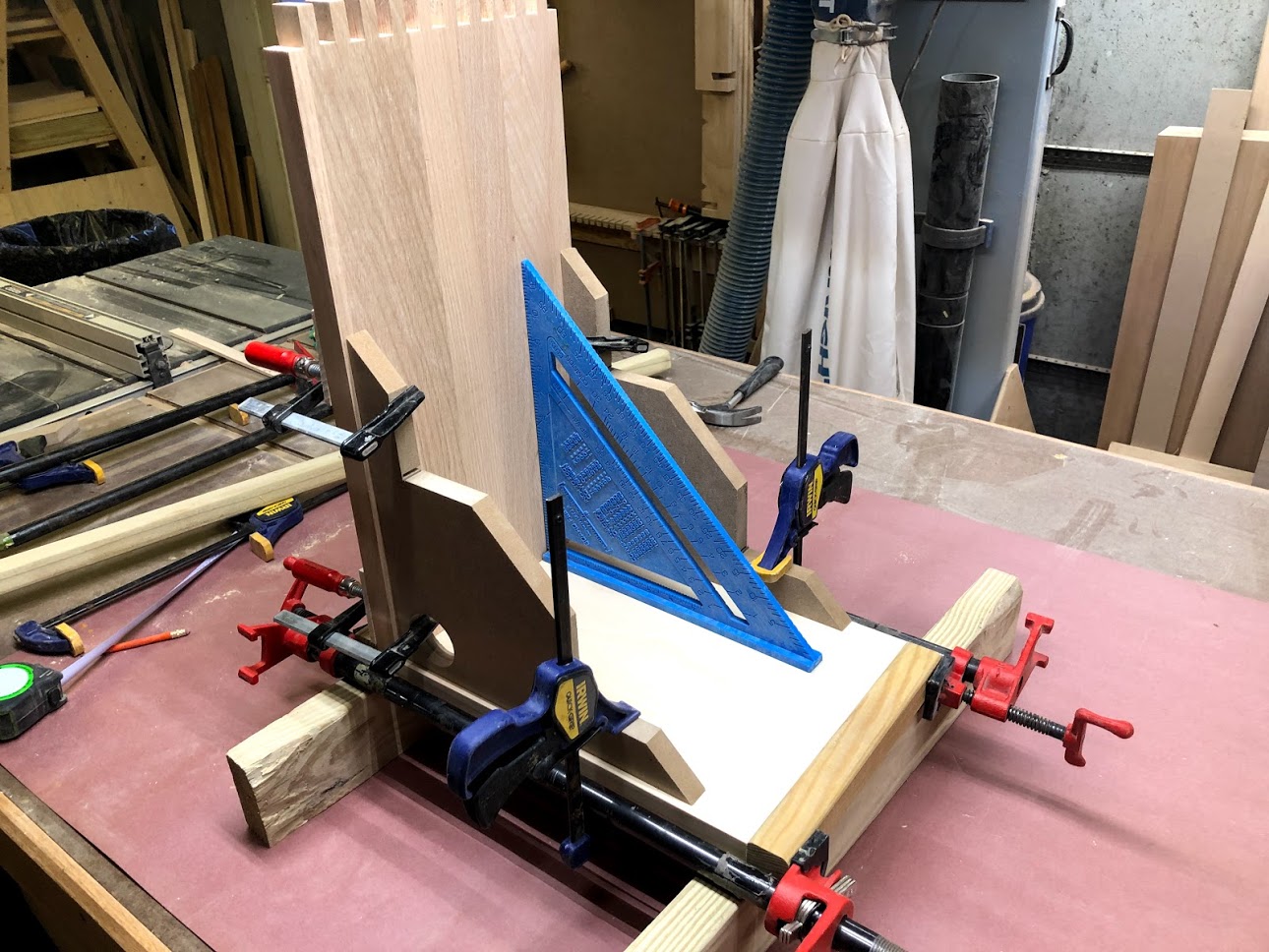

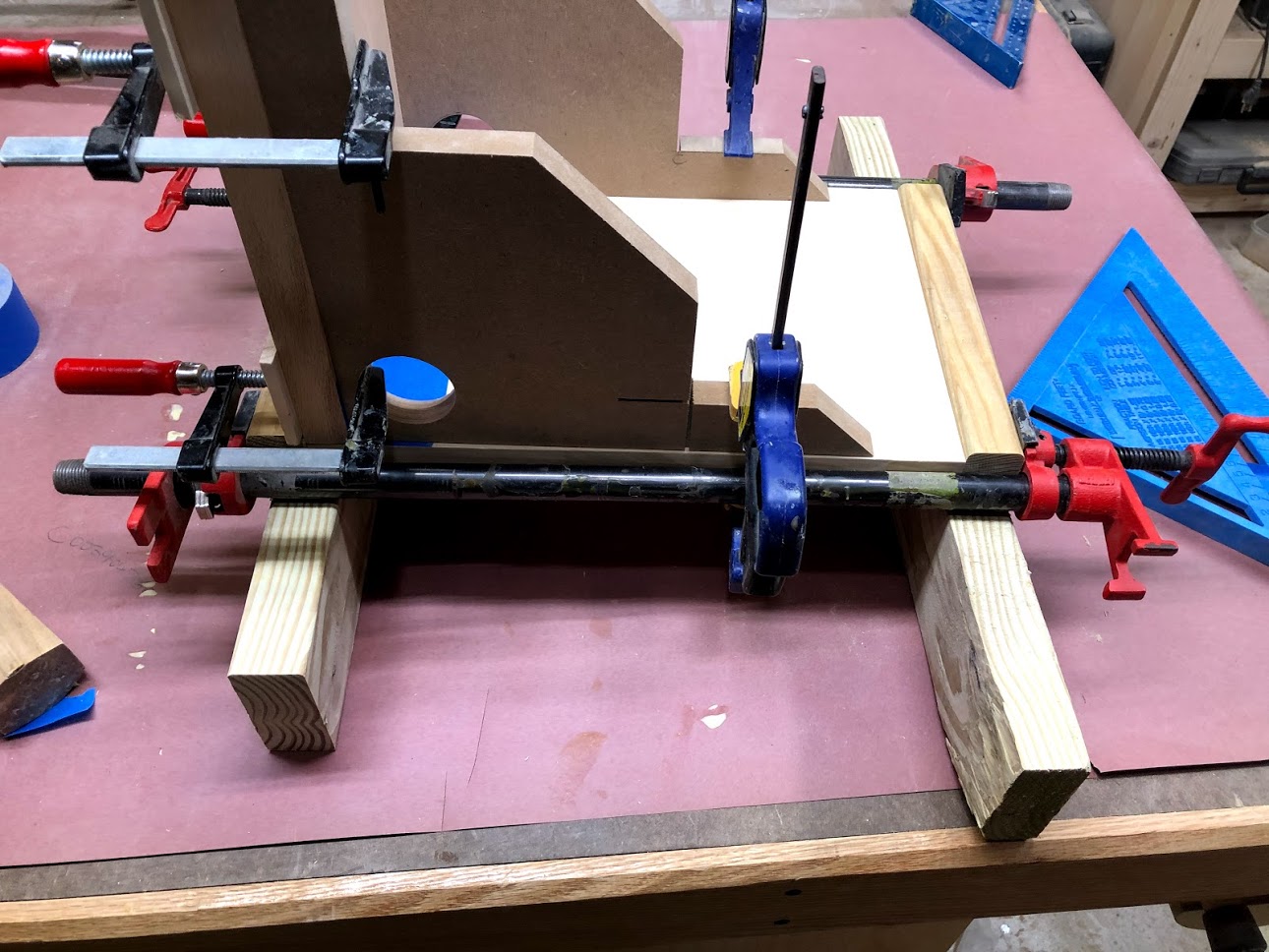

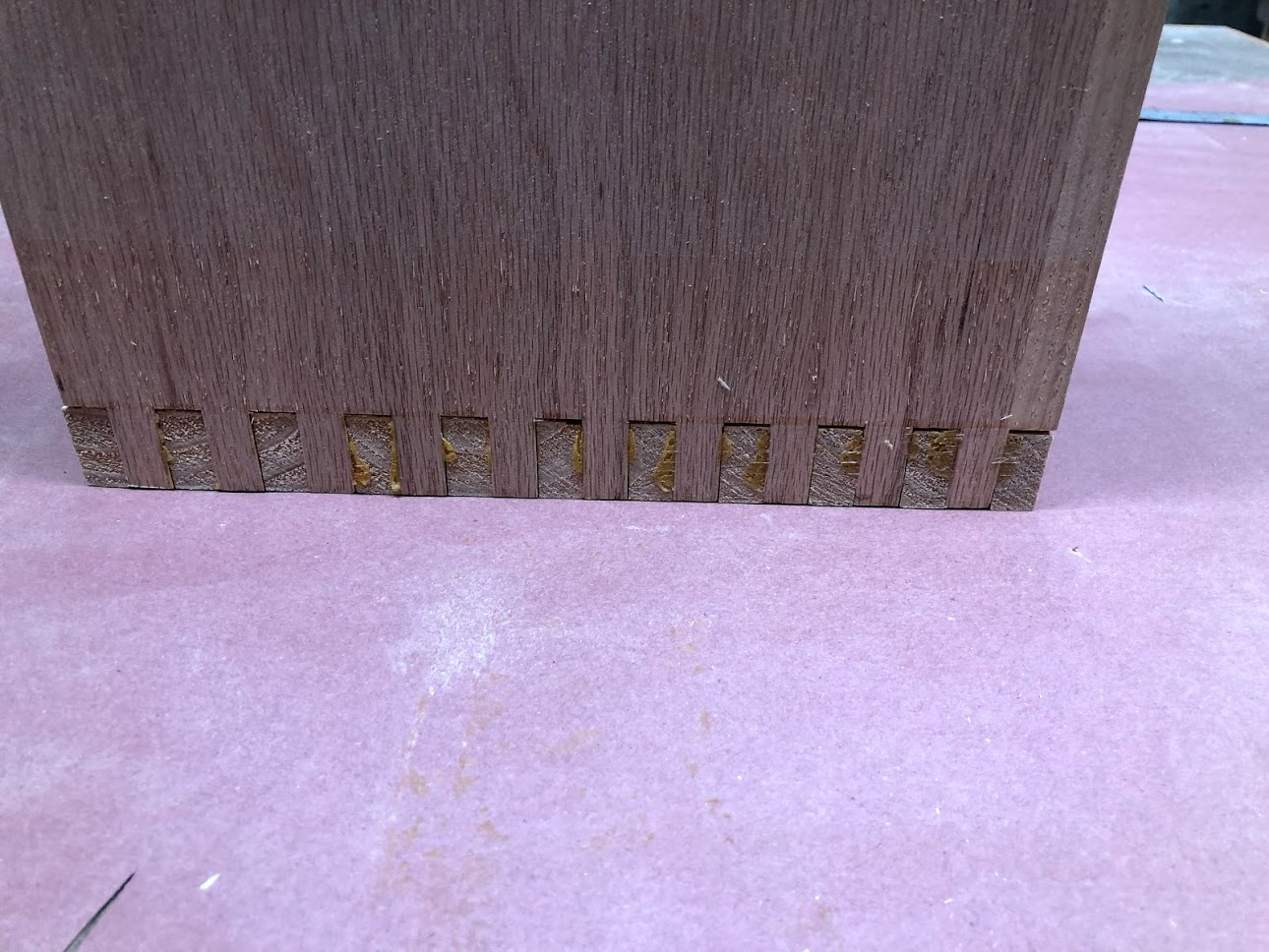

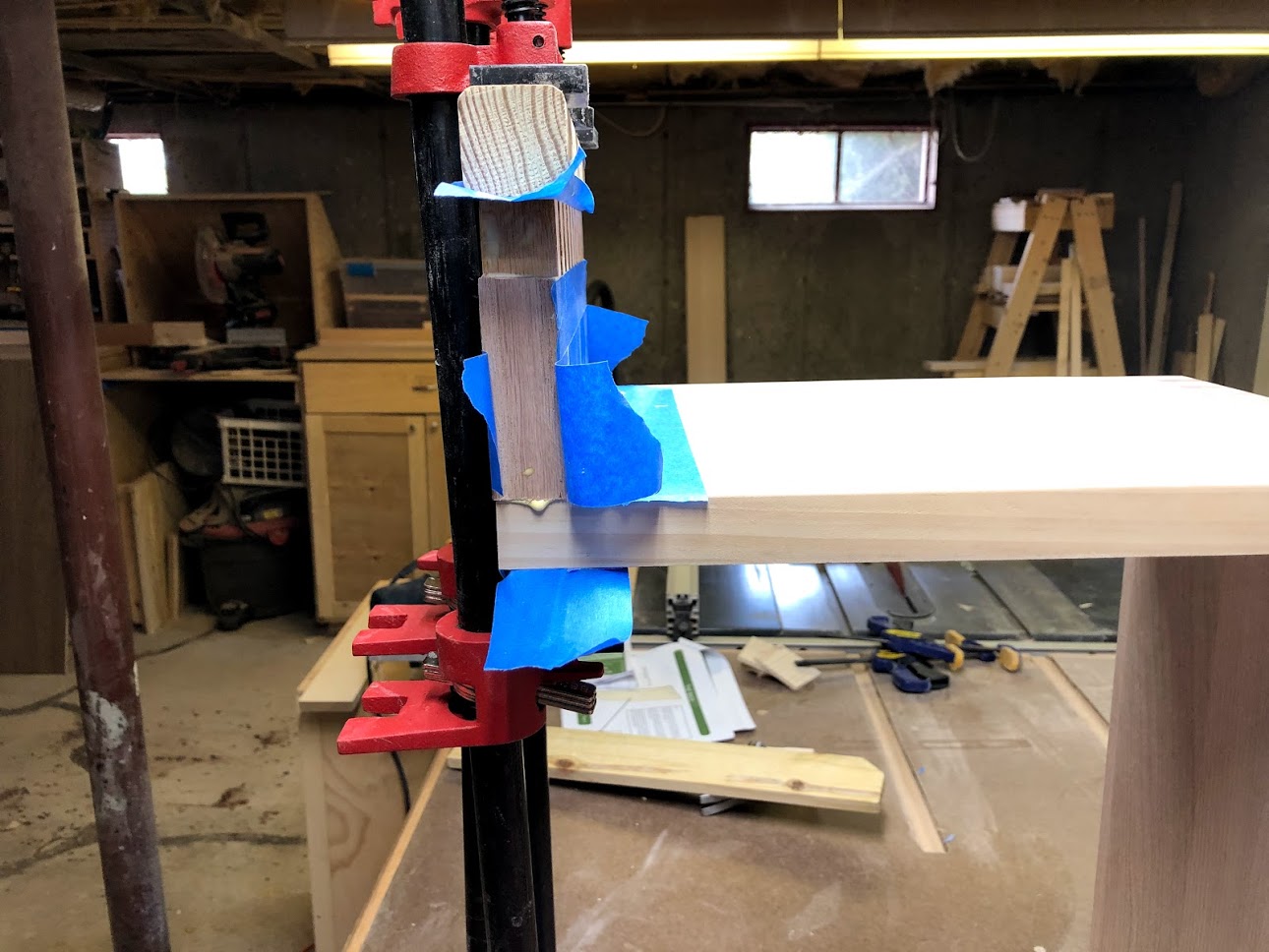

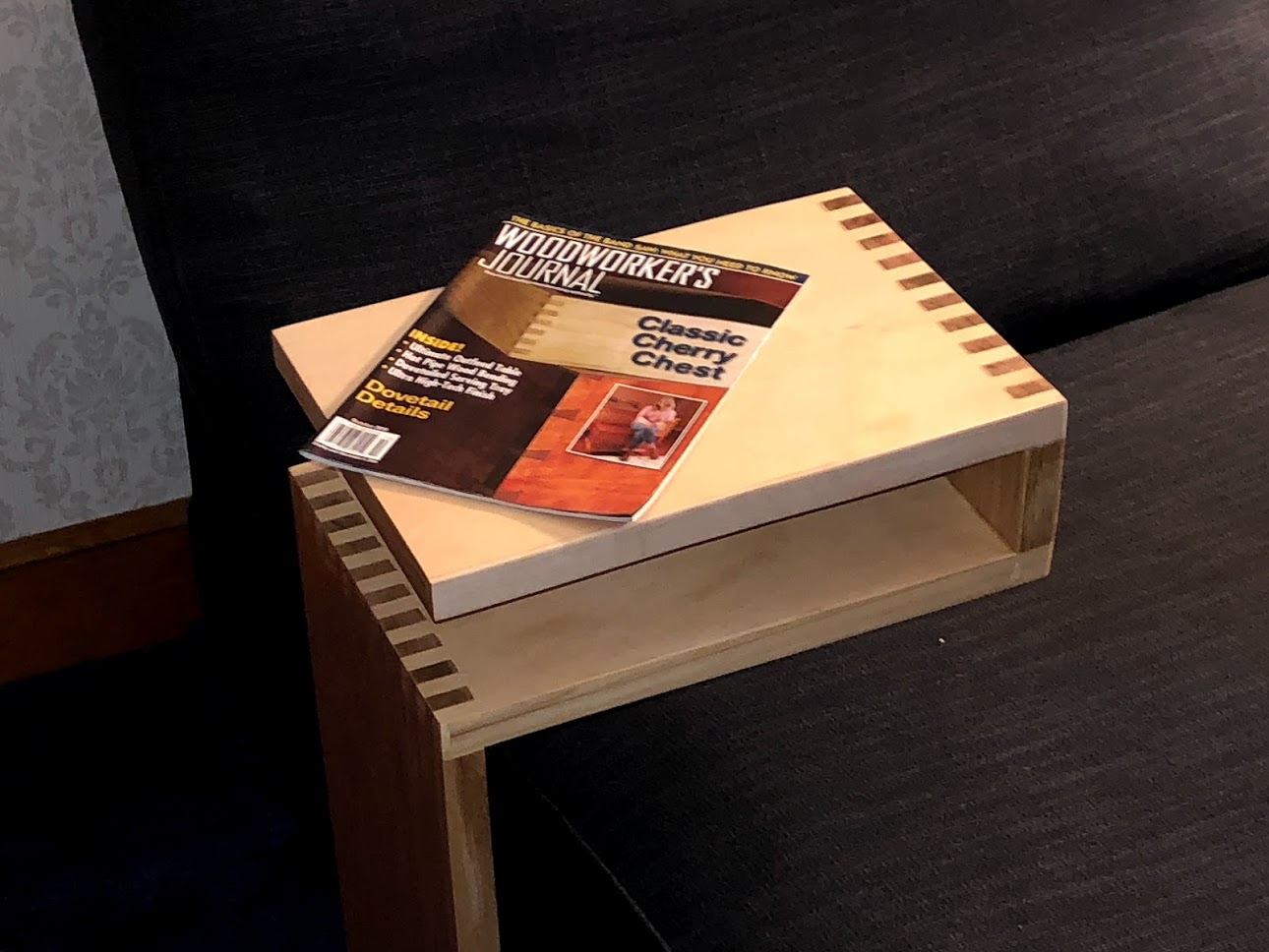

The joinery I used was traditional tongue and groove with inlaid panels on the front and sides of the box. I used frame and panel construction because it allowed me to incorporate more design features into the aesthetics of the window box. I was able add grooves to the panels that made up the front and sides to further enhance the look of the box and not just have solid wood panels beside each other and to be hones I really like the look of the window box and its very pleasing to the eye.

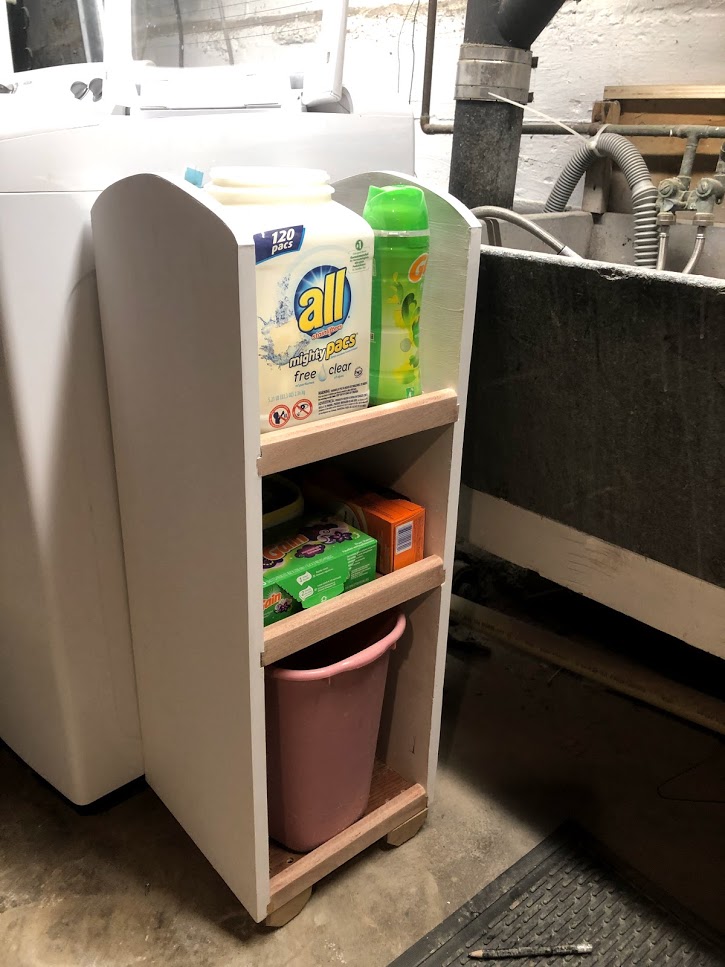

I also used plastic liners to go into the box so as that I could remove the it in order to put plants into the them then just place it back into its home.

To mount the window boxes I purchased some black Roth iron L brackets and secured them to the balusters on the front porch. and then just screwed the planter onto them.

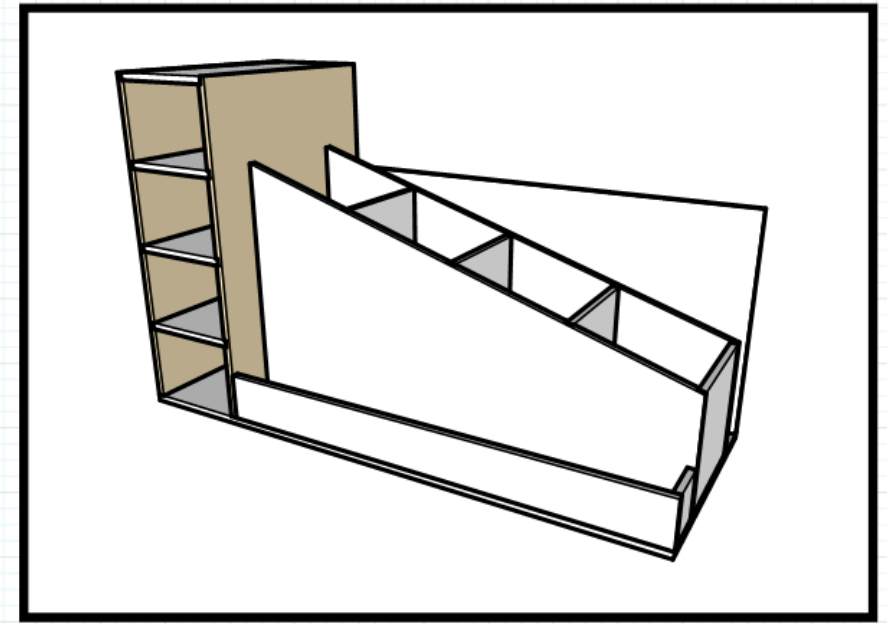

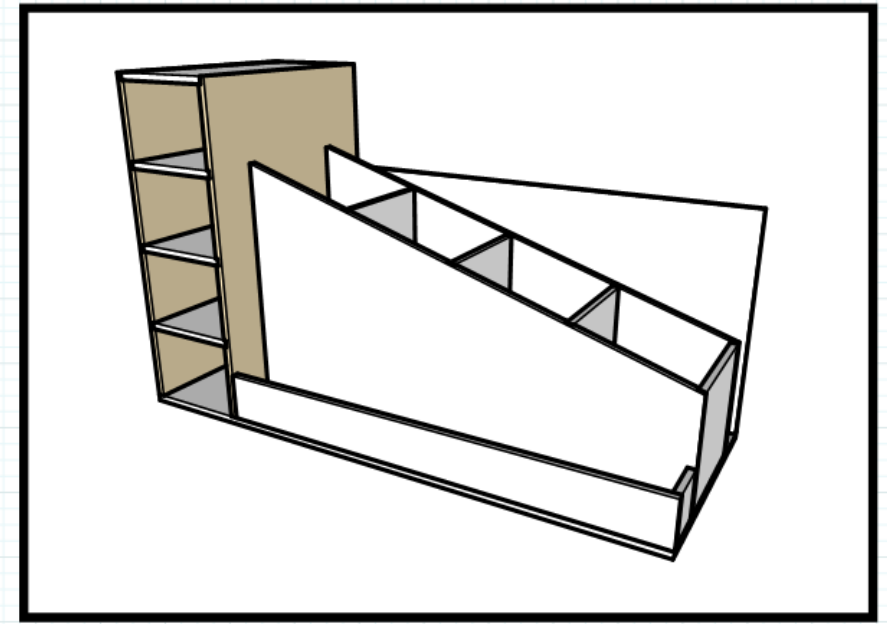

Below is a compilation of pictures with the finished window box. Also I did make an entire set of plans for both size boxes and I will post them soon I just need to tweak a few things to make them ready.

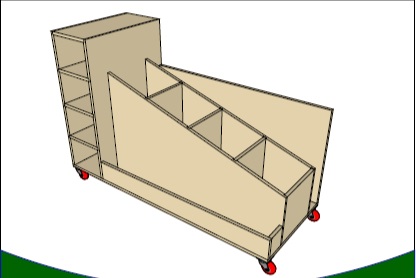

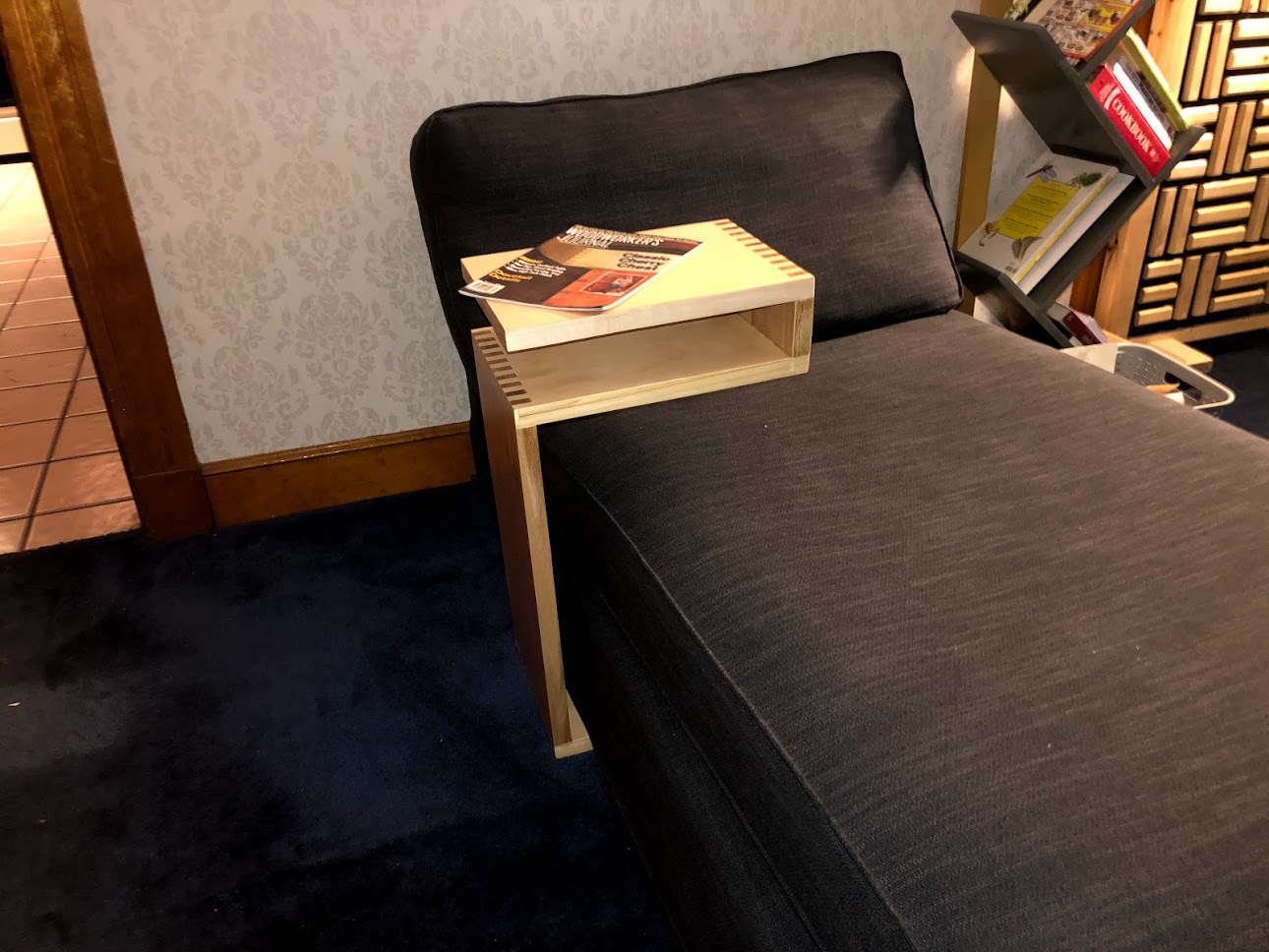

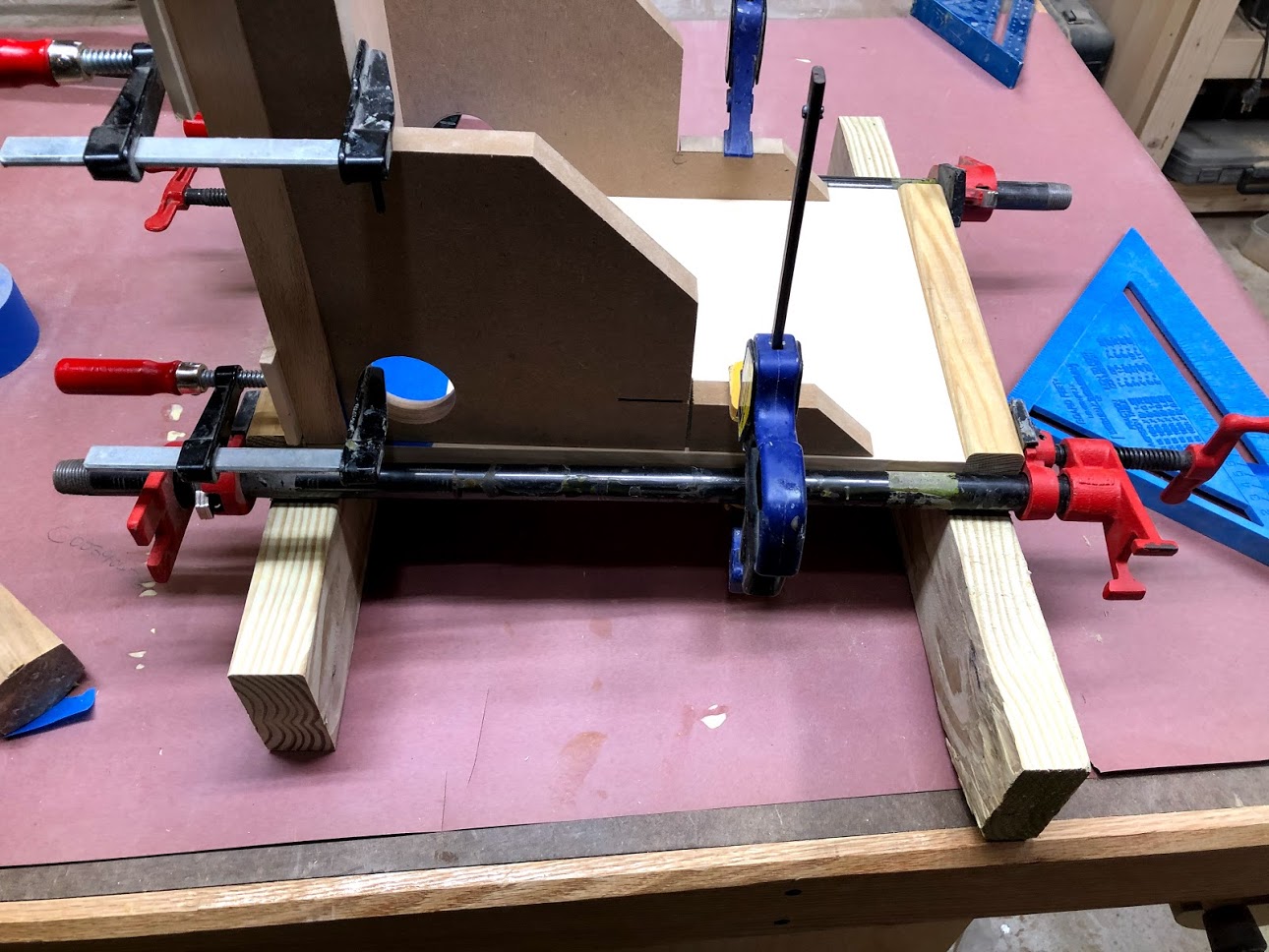

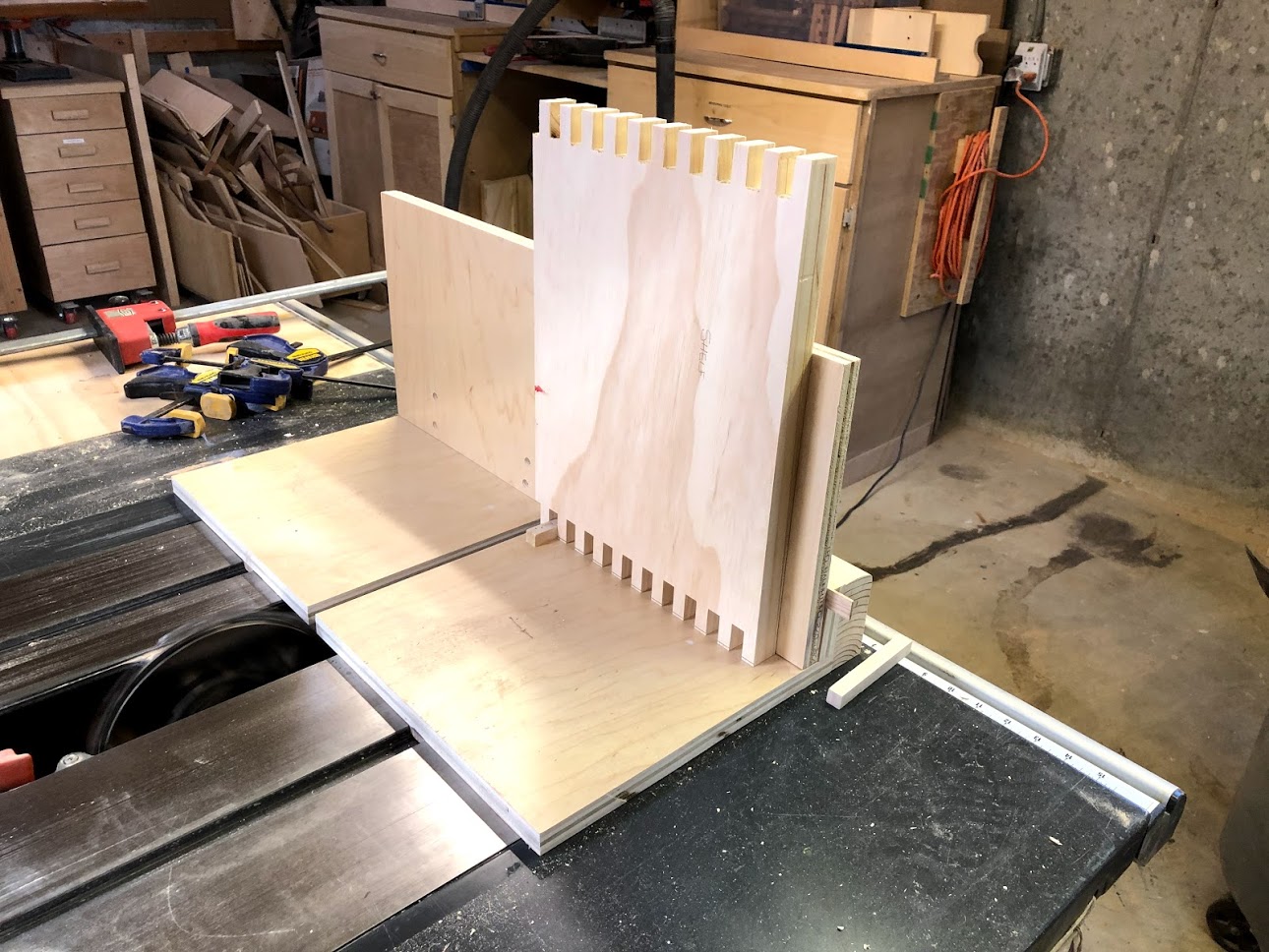

PRESSURE TREATED WINDOW BOX

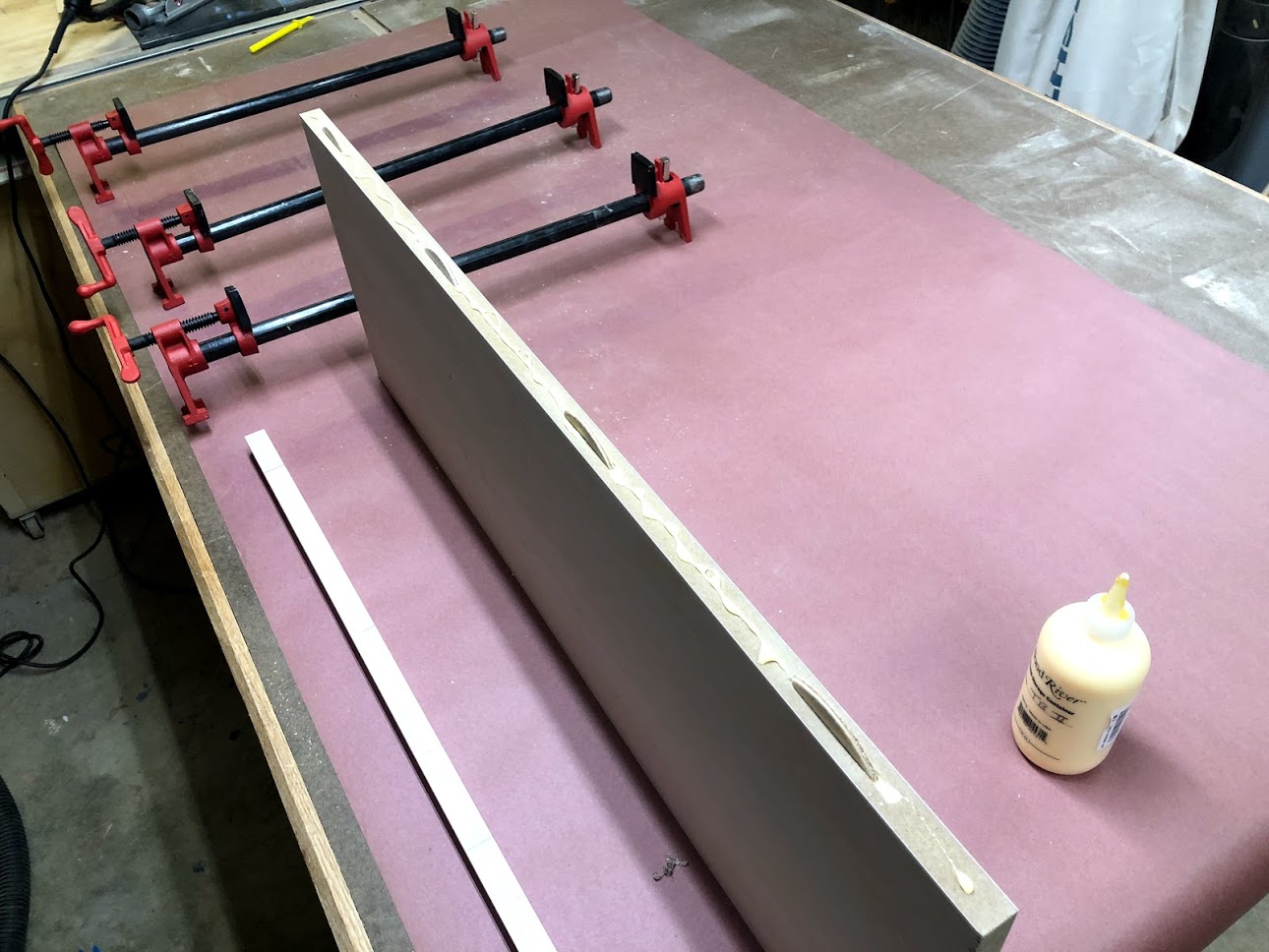

The pressure treated window box was made because I decided to make a few more and to be honest the cedar was such a difficult wood to work with as I got in the local home center anyway these windows bocxxes are basically made the same way as the Cedar one that I made with a few slight differences and that basically is they are only 24” long as I didn’t need them that long but the everything else is the same from the parts to the joinery and method of construction all the same.

These 2 window boxes were to be housed off the back deck in my back yard and will be mounted to the deck fence basically in the same manner as the cedar one I made for the front porch.

These window boxes also cost a lot less than the cedar and to be hones they look as good as the cedar one with a lot less of the construction headaches I had using the cedar.

I will be selling plans that I made to make these window boxes soon I just need to finalize them, well thanks for reading this article. I did make a project blog on making the larger cedar window box if you would like to read it I will leave a link below.