Phase 2 of the project deals with the Left & Right Sides. Basically the sides are made from 5 parts and if your familiar with Frame & panel construction you can make them easily.

I broke this phase down into the following steps:

The parts

Joinery of the Stiles and Rails

Making the panel

Additional Joinery

Some Router Work

Assembly

THE PARTS

The side is made up with the following parts:

Left & Right Stile (Vertical Pieces)

Top & Bottom Rails (The Horizontal Pieces)

1 Panel (Basically the inside of the frame)

Here you can see the left side and its labeled parts, the right side has the same parts but the joinery positioning is a little different, but Ill get to the joinery a little later.

JOINERY

The stiles are the left and right vertical pieces of the side and these all need a groove cut into the edge of the boards thickness spanning the entire length of the part. Although I will cutting the same groove into these parts its crucial that you place the groove on the correct edge or the joinery will not come together to wrap the panel and house the rails.

CUTTING THE GROOVES

Although I am showing the stiles and rails in this image its because I need to cut a groove along the inside edges of the all parts. Basically a groove is cut on the center of the workpiece and is cut all the way along its edge.

The groove is 1/4” wide x 1/2” deep and centered on the workpiece thickness, although I thought the workpiece was 3/4” thick its evident here that its not but that was my problem to remedy and hopefully your stock is actually 3/4”.

To cut the groove I installed a 1/4” wide dado stack blade in my table saw and move the rip a 1/4” away from the blade.

The grooves are cut because I will be fitting the center panel inside this frame work .

CUTTING THE RAIL TENONS

My next piece of joinery to do only applied to the rails as this is how I closed the panel off, I needed to cut a 1/2” long tenon. In this image you can see that I have my rails in a horizontal position and is back up by my miter gauge and sacrificial board to back up the cut (this reduces tear-out).

In my table saw I widened the dado stack to 1/2”, and lowered the depth of cut to 1/4” and made 2 passes on each end of the board and it revealed the tenon. This tenon is housed in the grooves that we already cut into the edges of the stiles.

THE INSIDE PANEL

To complete the frame and panel side of course we need to make the panel, in the previous steps we created grooves on the inside edges of the rails and stiles, these were cut to house the center panel.

As you can see I have the panel laid flat on the table saw and in the saw I have a 3/8” wide dado stack raised a 1/4” high and a sacrificial board attached to the rip fence so I don’t damage my fence). Next I run all four edges on both faces of the panel to create a tongue, these tongues on all four sides of the panel get housed in the grooves.

Here you can see the profile of the panel, the top and underside of the panel is removed creating a tongue.

ADDITIONAL JOINERY (Part 1)

Since There are 4 sides to any box I needed a housing method to find homes at all 4 corners of the box, in this illustrated diagram you can see the left and right stiles (pink) and where I needed to locate the groove and tongue so as that I could complete the joinery of the back and front of the box

ADDITIONAL JOINERY (Part 2)

Since I needed a method of joining the side to the window box back and front I needed to create a joint so as that when it came to gluing up the box everywhere had a home. So I needed to cut some more grooves. In this image you can see the left stile on its face about to receive the groove that the back will connect into. Again this groove is positioned a 1/4” from the edge and is again a 1/4” wide x 1/2” deep.

ADDITIONAL JOINERY (Part 3)

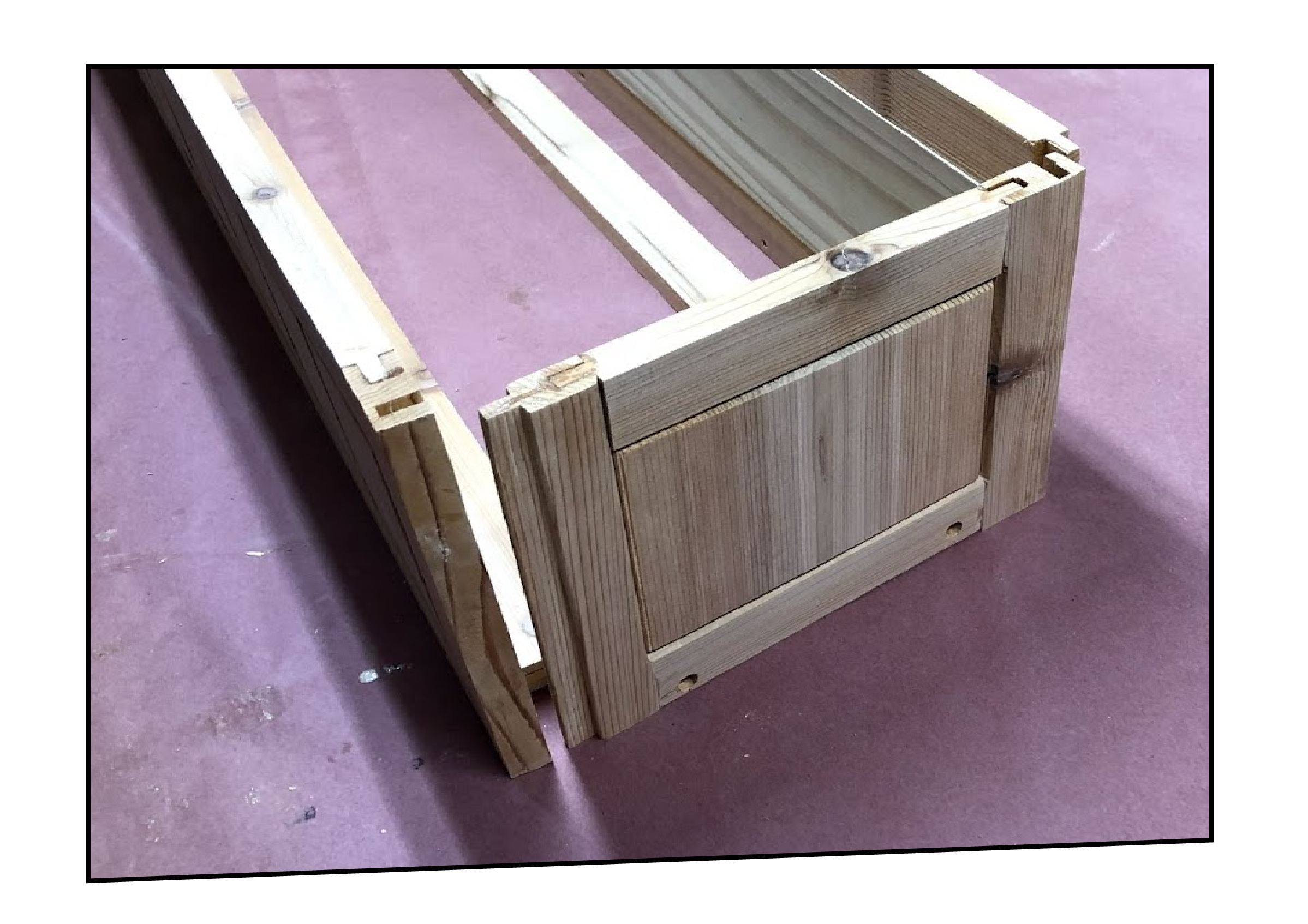

I am most definitely jumping ahead using this image but you can see the connection pints that I needed to make to the sides, The left side stile shows a tongue and the right side stile shows the groove this is how I attached the front and back of the box to the left and right sides.

Here is the completed side panel with the router groove all cut into the center of the assembly.

SOME ROUTER WORK

Although this is an optional step and could of simply left the side panel all flat and no character to it with a basic frame and panel design and sometimes I quite like that look. This time I decided that I wanted to define edges of the inside panel and make it stand out some more. So I used my router installed with a “V Groove” router bit.

THE PANEL ROUTING

Routing the panel is easy enough as I just need to route the edges of the panel make sure your not routing the tongue as that will be hidden, add the router profile to what is left and will be exposed on the side. I just lowered the bit in the router table and just the right side of the bit is kissing the panel.

THE STILES

These parts are some what more demanding because I don’t want to route the entire edge of the part, I only wanted the parts that came in contact with the panel visually. This is called a stop routing ad there are a ton of articles online on how to complete it the task.

Here is an image of the “V GROOVE” bit in the router.

Here you can see the subtle little groove cut on the right side edge, but boy does it make a difference.

ASSEMBLING THE SIDES

Assembling the side was a pretty simple affair I basically applied glue to the tenons on the rails and installed them into the left and right stiles. This is the only glue that I applied to the entire side and there is a good reason. I wanted the inside panel to have freedom of movement because of seasonal humidity, these climate changes can break apart a project because wood expands and contracts within different seasons, and I needed the center panel to have that freedom to move within the frame work.

ORIENT THE PARTS

I usually do a dry assembly of the parts and rehearse the glue up, but this wasn’t really necessary as the glue up was small.

ALL CLAMPED UP

Here you can see both the left and right sides all glued and clamped up I left this to dry overnight.

That wraps up Phase 2 of the project and the sides came out ok I was happy enough with them but this cedar is proving difficult but I am satisfied with how they came out. Next up is assembling and making the front of the box, this phase most definitely has the most work to it but it has a lot of similarities to the sides as it is just a much bigger frame and panel.